An important feature of 3C electronic products is their highly exquisite appearance. In addition, accessories require precision processing and high-speed machining.

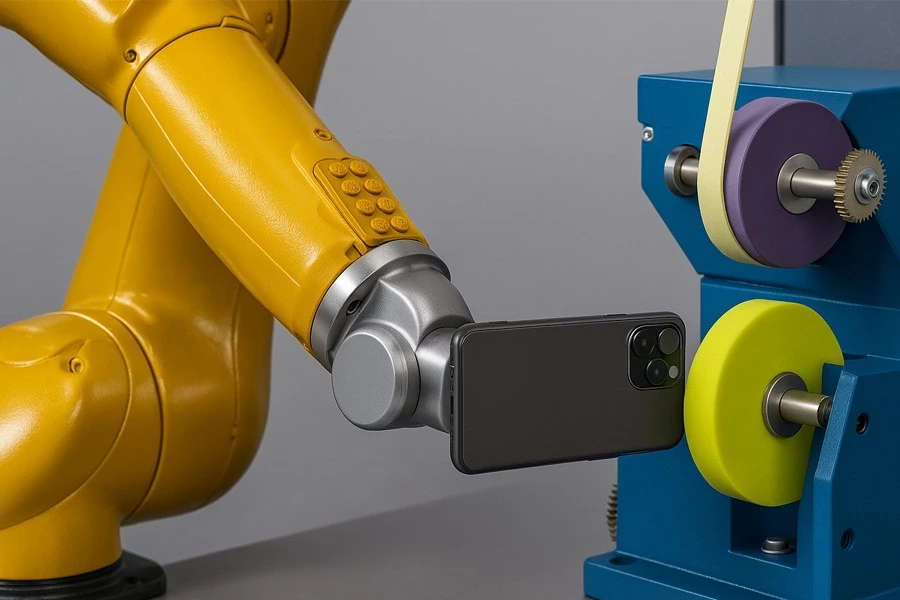

The Kingstone robot fully automatic grinding and polishing equipment system realizes the automation of workpiece grinding and polishing. It can be adapted to various new materials, improve the yield rate, shorten the processing time, and has the characteristics of precise, efficient and sustainable work.

Kingstone Robotics offers automated grinding, polishing, and deburring solutions tailored for the sports equipment industry. From golf clubs to fitness gear, our systems ensure precise finishes, dimensional accuracy, and improved durability. Designed to reduce labor costs, they help manufacturers achieve consistent quality and visual appeal at scale.

In the world of consumer electronics, finishing quality is both a functional and marketing imperative. Polishing enhances the device’s feel and look, grinding guarantees assembly fit and profile accuracy, and deburring eliminates the safety and structural risks of micro-burrs or casting flash.

Automating these processes brings consistency, scale, and ultra-fine control to an industry defined by slim form factors, premium materials, and high design turnover.

Polishing in 3C electronics is used to remove micro-scratches, oxide layers, and texture inconsistencies on surfaces such as aluminium, stainless steel, or coated plastics. It enhances surface gloss, increases corrosion resistance, and prepares parts for further finishing such as anodising or laser branding.

Common applications include smartphone housings, laptop panels, smartwatches, and camera frames—where a flawless exterior is essential to brand identity and consumer experience.

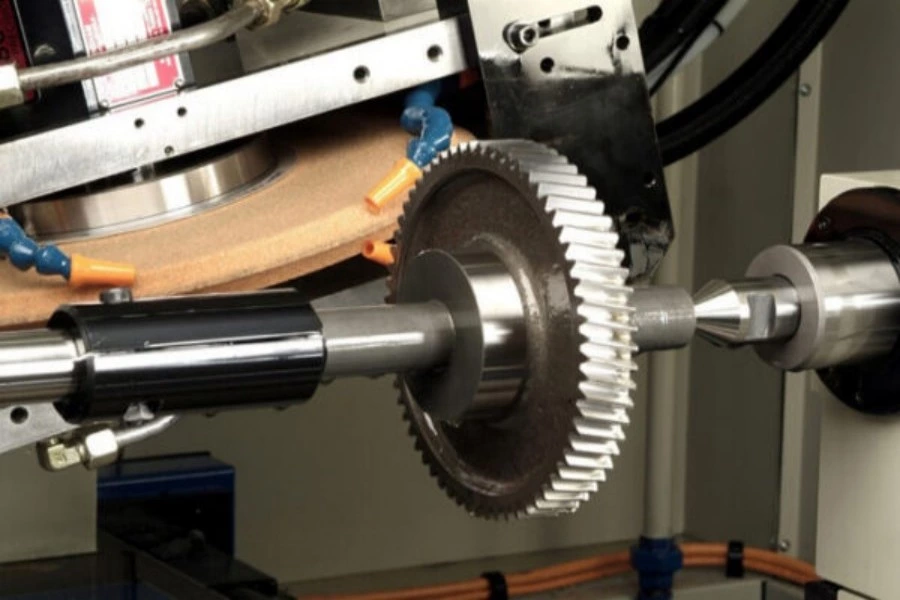

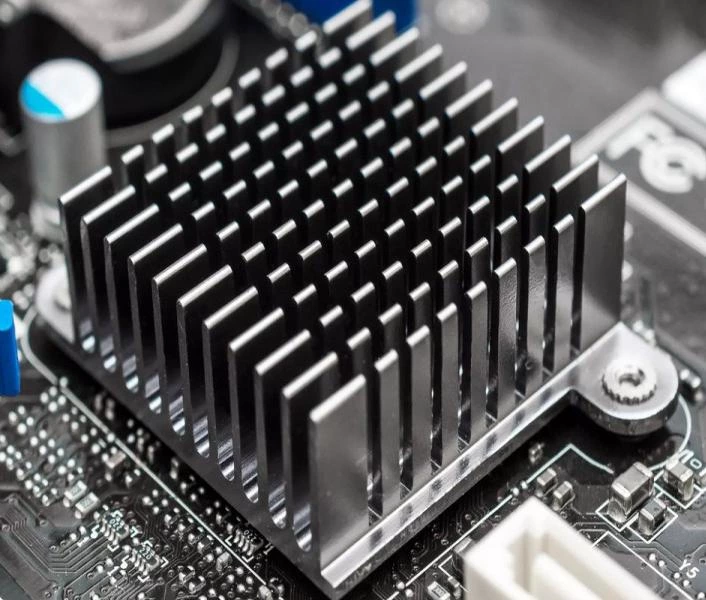

Grinding removes bulk material to shape the final geometry of a part. In 3C applications, this is essential for flatness (e.g., heat sink bases), profile accuracy (e.g., bezels, ports), or aesthetic edge shaping (e.g., unibody casings).

It’s especially critical for parts that must interlock with other components or dissipate heat efficiently, such as processors, battery trays, or contact panels.

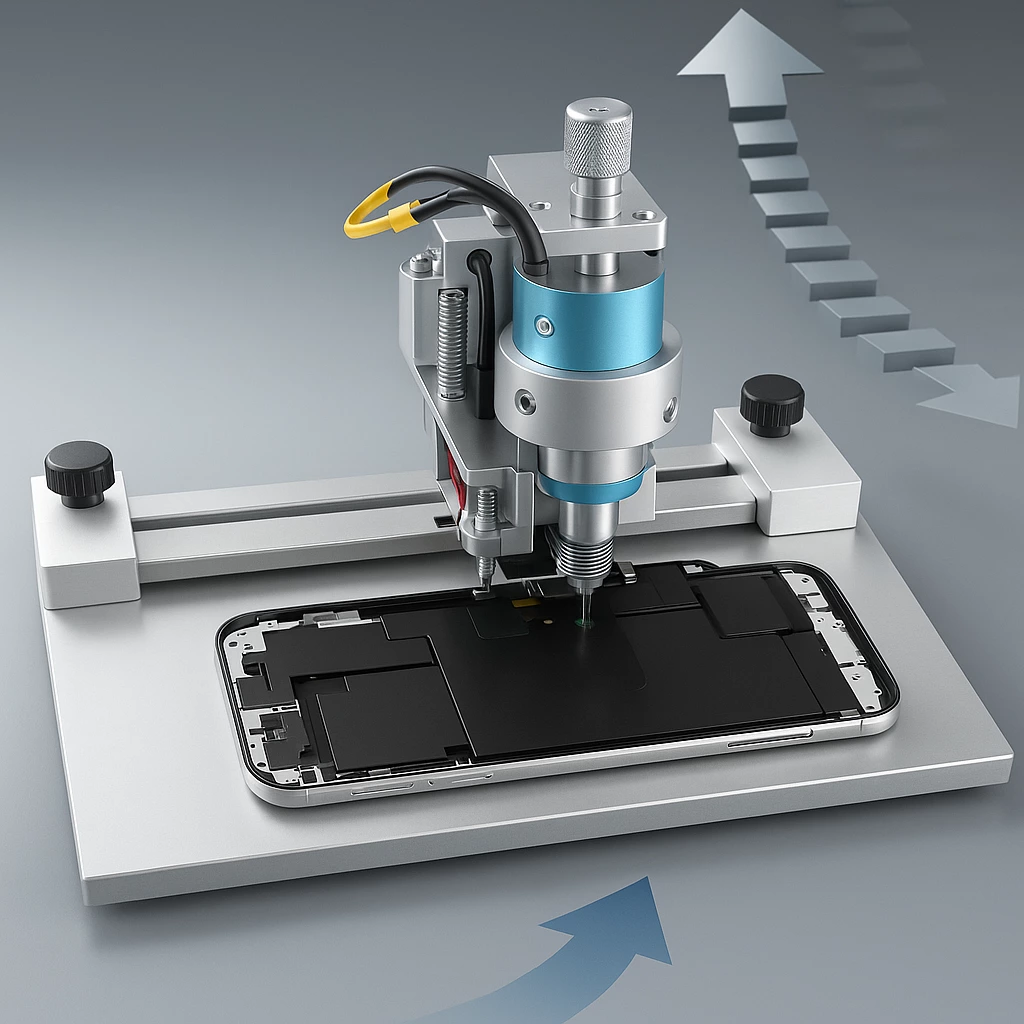

Deburring removes sharp metal fragments or extrusion flash left over from machining, die casting, or punching. These burrs may affect assembly tolerances, damage adjacent parts, or interfere with thermal management. Automated deburring ensures these risks are mitigated, consistently and without hand-finishing bottlenecks.

In 3C production, it’s essential for items like internal brackets, port housings, fasteners, and modular chassis parts.

Produces uniform gloss and texture for premium casings and visible components. Minimises human-induced variation, scratches, or inconsistent sheens.

Provides fine-tuned edge control and dimensional accuracy for heat-sensitive or shape-critical parts like heat sinks, laptop bases, and camera frames.

Removes micro-flash or extrusion burrs in compact electronic frames or slots, supporting clean assembly and long-term mechanical durability.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

For 3C products, visual uniformity defines brand quality. Automated polishing ensures the same surface gloss, edge radius, and texture across thousands of parts. Multi-axis robots control motion paths with micrometre precision and can adapt to complex industrial designs.

Used for:

Manual grinding or polishing often leads to inconsistent results—especially with complex surfaces or tight radii. Automated systems eliminate human error, tool over-pressure, and edge damage, significantly reducing defect rates and rework costs.

Applicable to:

3C components are increasingly thinner, lighter, and more delicate. Our robots use adaptive force control to handle these parts without deformation, while delivering consistent surface conditioning—even on multi-material composites.

Especially important for:

Automated polishing and grinding stations operate continuously, with minimal operator intervention. With multi-fixture design and fast tool switching, one cell can finish hundreds of parts per shift—making automation viable even in compact production lines.

Great for:

3C manufacturers operate under stringent cleanliness and ESD (electrostatic discharge) standards. Our robotic cells are enclosed, filtered, and ESD-safe—minimising dust, operator exposure, and contamination in high-sensitivity environments.

Valuable for:

3C products increasingly feature a combination of textures—such as matte sides, polished frames, and etched logos—within a single part. Robotic systems can be programmed to apply distinct surface treatments in sequence, using position tracking and tool-switch automation to achieve seamless transitions without part repositioning.

Ideal for:

• Smartphones with gradient brushed backs and polished edges

• Wearables with engraved or logo-specific textures

• Multi-finish tablet enclosures with integrated branding zones

DSLR camera frames, action camera housings, smartphone camera modules

Notebook chassis (aluminium unibody or magnesium alloy), docking base housings

Produces premium aesthetic finish on plastic, glass, or metal cases

Smartphone cases, tablet back covers, wearables housing

Luxury wristwatch cases, smart watch bezels, mechanical chronograph bodies

Laptop and desktop heat sinks, power supply radiators, LED cooling plates

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.