Grinding and polishing robots are one of many types of modern industrial robots. Used to replace traditional manual grinding and polishing products, including surface grinding, corner deburring, weld grinding, inner hole deburring, hole thread processing, etc.

Kingstone robotics polishing equipment can provide automated solutions through non-standard designs based on customer product needs, stabilizing the controllability of customer product quality and efficiency.

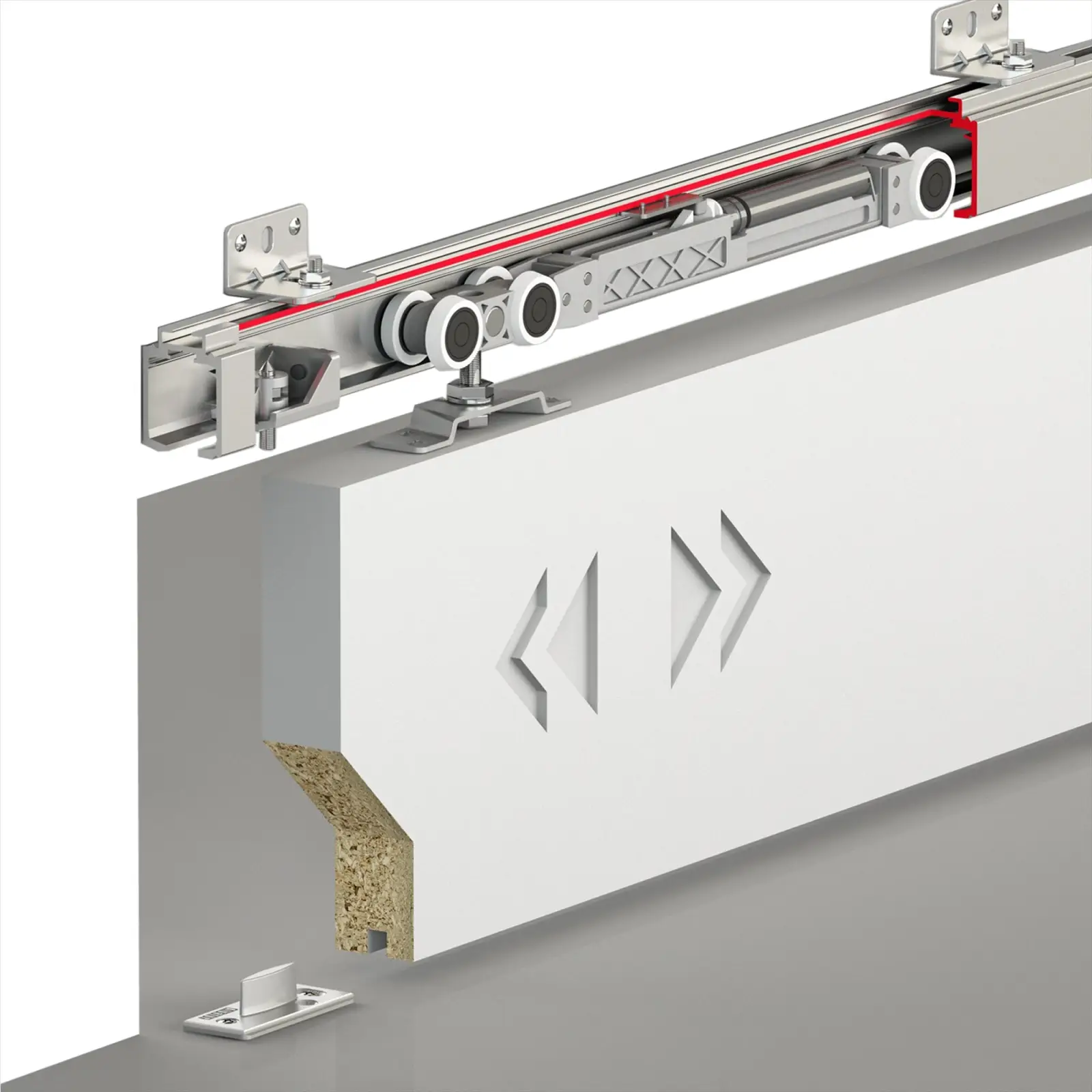

In modern residential and commercial interiors, furniture hardware components such as door handles, stoppers, rails, and locks serve as both functional supports and design elements. Whether they are brushed stainless door pulls or polished mirrored panels, these details shape user experience and product durability.

Kingstone Robotics delivers fully integrated robotic surface finishing solutions tailored for furniture hardware manufacturers. Our systems combine adaptive grinding, precision polishing, and micro-deburring in scalable workcells, supporting high-mix product lines and elevated design standards.

Functional hardware used in doors, cabinetry, rails, and furniture mirrors must satisfy more than mechanical fit—they must feel smooth, look elegant, and last under frequent use. Polishing removes surface inconsistencies, grinding corrects form and welds, and deburring ensures edges are clean and safe for handling.

With automation, manufacturers can meet modern architectural finish standards (brushed, satin, chrome, matte, mirror) without relying on labour-intensive manual work.

Polishing improves both the appearance and touch of visible surfaces. In furniture hardware, it’s used on stainless steel handles, chrome stoppers, anodised rails, and aluminum trims to achieve uniform gloss, reflectivity, or brushing patterns. It also prepares surfaces for coatings and increases corrosion resistance.

Grinding shapes the part by removing excess material or imperfections. It’s commonly applied to welded pull handles, stamped mirror frames, or assembled door rails. Grinding ensures the uniform profile and flatness required for perfect fit and aesthetics.

Deburring removes sharp edges, small projections, or machining remnants that are hazardous or visually disruptive. It is critical in lock mechanisms, brackets, stops, and fittings, improving assembly, functionality, and safety. Automation ensures edge uniformity across batches.

Delivers consistent gloss, grain orientation, and finish depth. Key for consumer-facing parts such as handles, knobs, and mirrored frames.

Prepares structural parts with clean weld removal, precise form, and consistent texture. Ideal for tubular hardware, rails, and welded brackets.

Ensures smooth, safe, and fitting-ready edges for small and medium metal components like stoppers and locks.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Surface consistency is vital in architectural fittings, especially when hardware appears in multiples across a space. Automated polishing and grinding deliver uniform brightness, brushing lines, and smooth curves.

Applicable to:

Manual finishing is slow and often inconsistent. Kingstone’s robotic systems can handle multiple parts per cycle with fast changeovers, enabling continuous operation while maintaining quality.

Ideal for:

Sharp or poorly finished parts lead to quality complaints and safety risks. Robotic deburring ensures smooth edges that meet industry safety and usability standards, reducing inspection and rework effort.

Critical for:

Even minor inconsistencies in surface finish can lead to early corrosion or wear. Robotic finishing prepares parts perfectly for electroplating, powder coating, or anodising—extending product life.

Benefits:

Kingstone systems are designed for flexible deployment—from small cell-based workstations to full-line integration. This allows manufacturers to upgrade part or all of their production for better ROI, less waste, and lower labour costs.

Perfect for:

Modern furniture hardware often combines metals, plastics, and composites—sometimes within a single component. Robotic finishing systems can adapt tool pressure, speed, and contact path in real time, handling material transitions and intricate geometries with precision that manual methods can’t replicate.

Suitable for:

• Handles with metal cores and polymer shells

• Decorative hardware with recessed or contoured features

• Multi-surface parts requiring differentiated polish zones

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.