In traditional manufacturing, especially in bathroom hardware production, polishing is a fundamental process, but it accounts for 30% of the total cost.

Due to rising labor costs and the harmful effects of dust generated by manual polishing on workers' health, recruiting labor for sanitary ware manufacturing has become a major challenge for many companies.

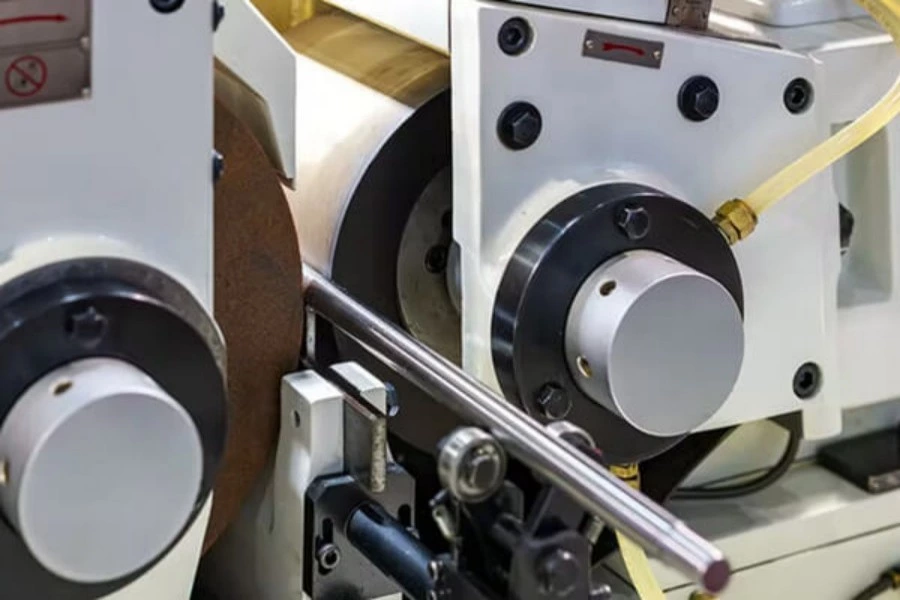

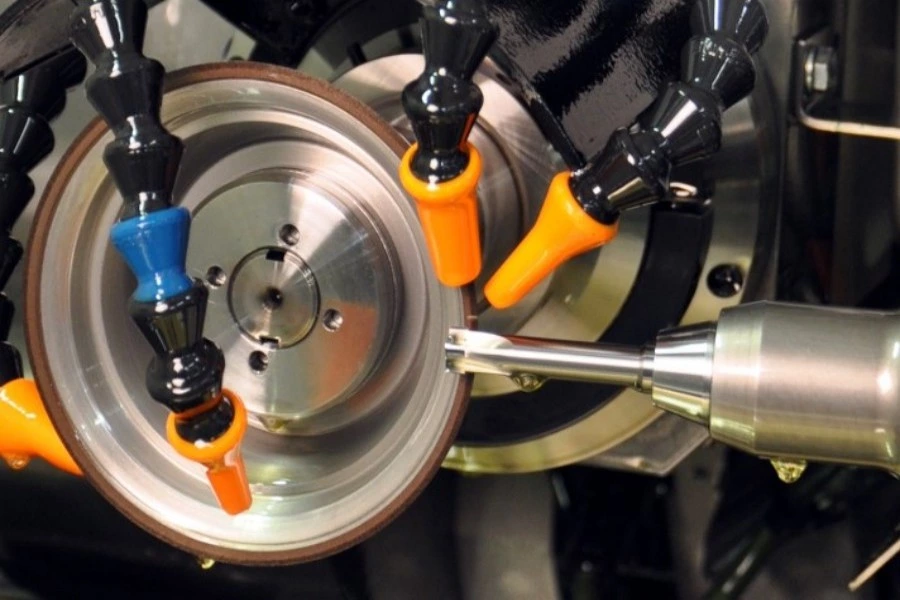

Many sanitary ware manufacturers have opted to upgrade by replacing manual polishing with intelligent robotic polishing equipment—such as faucet robot polishing systems—to eliminate manual labor in this process.

Additionally, products polished by robots exhibit higher quality, more uniform coloring, and smoother surfaces, making them more stable in humid environments and significantly increasing production capacity.

Bathroom hardware demands more than basic utility—it must combine visual elegance, corrosion resistance, and precise craftsmanship. From polished brass valves to satin towel bars, surface finishing defines product value.

Kingstone Robotics delivers specialized robotic polishing, grinding, and deburring systems for bathroom hardware. Our solutions ensure consistent quality, high efficiency, and reduced labor for brass and stainless-steel components.

Finishing processes are critical in bathroom hardware, where aesthetics, hygiene, and tactile comfort must all be optimised. These components are constantly exposed to moisture, chemicals, and human touch—demanding perfect surface quality and precise assembly fit.

Automation replaces inconsistent manual finishing with clean, repeatable processes suited for everything from premium faucets to mass-market towel racks.

Polishing is the process of removing surface irregularities, fine scratches, or oxidation layers to achieve a smooth or mirror-like finish. In bathroom hardware, polishing is often used on brass, stainless steel, or zinc alloy components to achieve decorative aesthetics and corrosion resistance. It’s especially important for visible parts such as taps, knobs, and towel bars.

Grinding is a material-removal process that uses abrasive tools to flatten or contour a surface. In this sector, grinding is often applied to welded structures (like towel bars or frames), castings (such as handles), and parts requiring consistent flatness or profile control before polishing or coating.

Deburring removes sharp edges or leftover burrs from stamped, cast, or machined parts. Unfinished burrs can cause injury, compromise fitting during assembly, or affect downstream plating. Robotic deburring ensures smooth, safe edges on functional elements such as hooks, brackets, and knobs.

Delivers uniform surface shine across large batches of plated or brushed products. Robotic polishing ensures a consistent gloss level, edge rounding, and touch-safe finish for decorative items.

Used to eliminate weld seams and flatten mounting surfaces. Robotic grinding ensures the structural uniformity of rails, bars, and handles before finishing.

Removes flash, sharp edges, and casting irregularities from small hardware parts. Essential for user safety and for meeting plating/coating adhesion requirements.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Whether for chrome-plated towel bars or satin-brushed knobs, consistency is key to brand identity and product quality. Robotic systems deliver uniform finishes without operator fatigue, ensuring every piece meets aesthetic and tactile standards.

Particularly valuable for:

Robotic polishing and grinding systems can achieve smoother surfaces, eliminating microscopic flaws that attract corrosion or tarnish. This improves not only visual appeal but also lifespan—essential for bathroom environments where humidity and chemical exposure are constant.

Ideal for:

One robotic cell can replace multiple manual stations, running continuously with predictable cycle times. Multi-part fixtures and tool changers allow rapid processing of different component types without sacrificing speed.

Best suited for:

With adaptive force control and path accuracy, robotic systems reduce the risk of over-polishing, gouging, or under-finishing. Automated in-process inspection ensures early defect detection and fewer rejections.

Key advantages for:

Manual polishing and grinding are labour-intensive, noisy, and hazardous. Robotic automation removes operators from harsh environments, lowers risk of injury, and helps manufacturers optimise headcount while retaining quality control.

Perfect for:

Modern bathroom hardware often includes multi-angled fixtures, recessed grooves, and decorative contours that demand controlled, repeatable finishing. Robotic systems equipped with multi-axis motion and tool flexibility can precisely follow intricate geometries—delivering flawless aesthetics without compromising structural integrity.

Applicable to:

• Designer faucet bodies and sculpted tap handles

• Multi-texture towel rack assemblies

• Bespoke bathroom sets with signature contouring or inlays

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.