Modern sports equipment products have developed from a single variety to a series, and the requirements for their beauty and decorative effects are getting higher and higher. The materials used in sports equipment have expanded from traditional iron alloys and low carbon steel to zinc alloys, aluminum alloys, stainless steel, plastics, fiberglass and various composite materials.

Kingstone robot polishing & grinding unit not only polish brass, zinc alloy, aluminum alloy, stainless steel, titanium and other metal materials, but polish plastics, glass and other non-metallic materials. The polishing effect far exceeds the level of its peers. It is the preferred manufacturer at home and abroad!

Kingstone Robotics provides automated grinding, polishing, and deburring systems for sports equipment, ensuring precision, visual appeal, and durability. Ideal for golf clubs to fitness gear, our solutions enhance finish quality, meet tight tolerances, and cut labor costs—supporting high-performance, cost-effective production for sports hardware manufacturers.

Whether it’s refining the surface of a dumbbell, deburring a stirrup pedal, or grinding a titanium driver head, our solutions enable scalable, repeatable production without compromising craftsmanship.

Learn More About KS Ask For Support

Sports equipment surfaces aren’t just cosmetic—they affect performance, grip, aerodynamics, safety, and user satisfaction. In high-end segments like golf, equestrian gear, and marine hardware, even micro-imperfections can degrade performance or brand value. Polishing removes roughness, grinding sculpts the geometry, and deburring ensures safe contact surfaces. Automation brings repeatability and speed to these delicate finishing operations.

Delivers consistent brightness, smoothness, and texture across batches of fitness or marine components—ensuring showroom-quality appearance and protection.

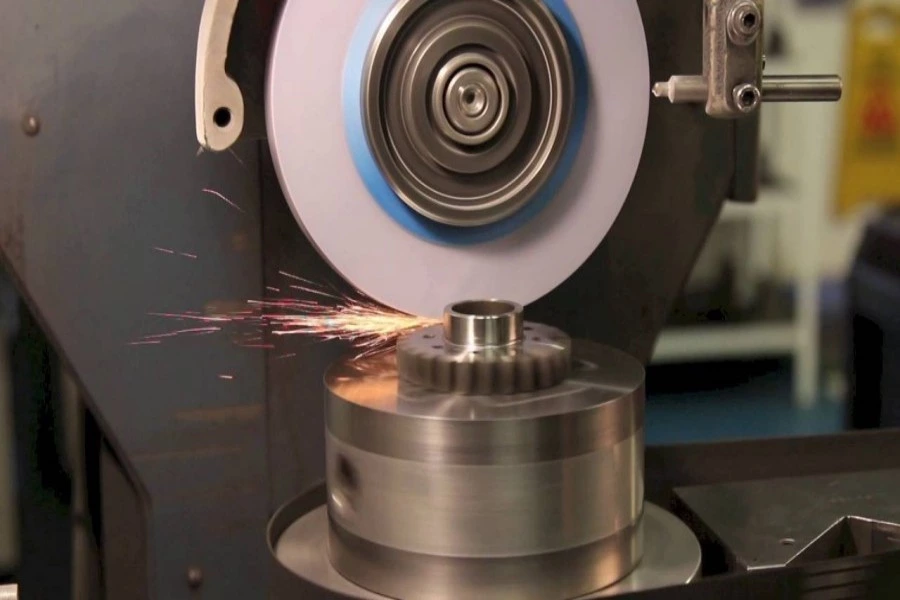

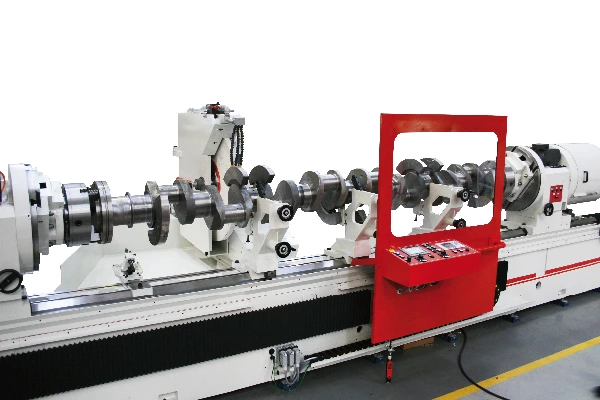

Ensures balance, symmetry, and form—especially in performance-dependent products like golf clubs or crankshafts, where precision affects functionality.

Improves handling safety and assembly quality for products like stirrups and dumbbells, eliminating the need for manual touch-ups.

Delivers consistent brightness, smoothness, and texture across batches of fitness or marine components—ensuring showroom-quality appearance and protection.

Ensures balance, symmetry, and form—especially in performance-dependent products like golf clubs or crankshafts, where precision affects functionality.

Improves handling safety and assembly quality for products like stirrups and dumbbells, eliminating the need for manual touch-ups.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Consumers expect fitness and sports gear to be not only durable but visually flawless. Robotic automation maintains consistent surface texture, gloss level, and part geometry, eliminating the visible variations often introduced by manual finishing.

Perfect for:

With automated cells, manufacturers can process dozens of parts per hour with minimal operator intervention. Multi-part fixtures and dual-arm systems enable continuous production, helping brands meet high seasonal or export demand.

Ideal for:

Grinding and polishing involve rotating machinery, airborne dust, and repetitive movement—all risk factors in manual environments. Automation eliminates exposure and enables clean, enclosed workspaces.

Benefits include:

Robotic systems ensure process stability and in-line part verification, reducing the cost of defects or reprocessing. With automated path correction and force-sensing, even complex surfaces can be handled reliably.

Critical for:

For sports equipment manufacturers pursuing international growth, automation supports flexible part types, consistent quality, and compliance with global standards (e.g., ISO, RoHS). Combined with branding finishes like laser logos or custom polishing patterns, it ensures you deliver both form and function.

Sports equipment often features ergonomic contours, compound curves, and material combinations like rubber-metal or carbon-aluminum. Robotic surface finishing systems offer multi-axis motion and adaptive force control to accurately polish and grind across varying geometries and material boundaries—delivering high-quality results without damaging sensitive surfaces.

Applicable to:

• Curved handlebars or bike frames with welds and tubing transitions

• Composite-core tennis rackets or ski poles

• Multi-textured fitness machine components with rubber inserts or metallic shells

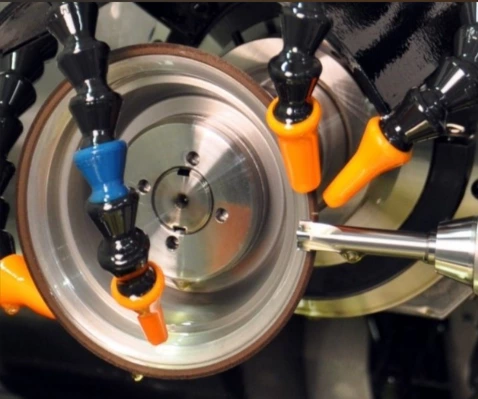

High-precision 6-axis robots with adaptive force control manage complex golf club geometries. Custom end-effectors use interchangeable abrasives for stainless steel or titanium. Integrated vision ensures precise alignment and consistent results.

Automated grinding of faces, soles, and cavities optimizes weight and finish. Sequential polishing enhances corrosion resistance and appearance. Real-time monitoring ensures dimensional and surface quality.

• Consistent weight/balance for performance

• Enhanced finish for aerodynamics

• Reduced labor and higher efficiency

Golf irons, wedges, putters, drivers

Also ideal for: brushed dumbbells, polished titanium heads, and branded powder-coated parts.

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.