According to customers' products and needs, different robot polishing and grinding equipment are customized to meet the production requirements of different customers, help customers improve product quality and output, and create an unmanned production workshop.

Clothing machinery parts—like iron soleplates and sewing housings—demand precision, durability, and refined finishes. Their surface quality affects performance and brand perception.

Kingstone Robotics offers automated grinding, polishing, and deburring systems for the garment equipment industry, ensuring consistent results across metals and alloys while minimizing manual labor and production costs.

Clothing machinery components require not just structural durability, but also tactile and visual appeal—especially in customer-facing tools like irons or sewing machines. Polishing ensures smooth gliding surfaces, grinding defines fit and function, and deburring eliminates manufacturing residues that could damage fabric or cause operator injury. Automation brings control, repeatability, and scale to these delicate yet essential processes.

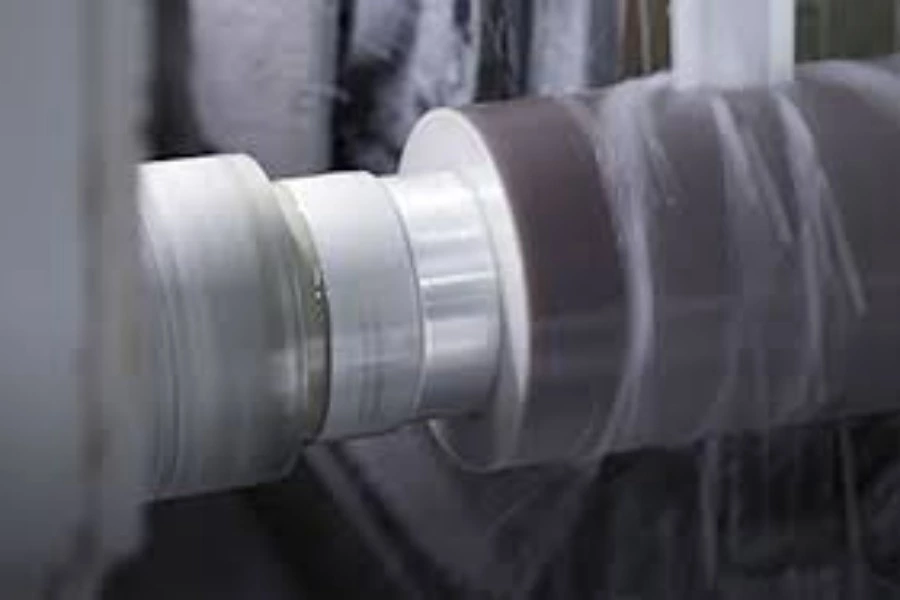

Polishing improves surface brightness, reduces friction, and enhances resistance to corrosion or fabric snagging. In this industry, it’s particularly useful for ironing plates, machine casings, and presser feet—ensuring a smooth surface that interacts safely with textiles.

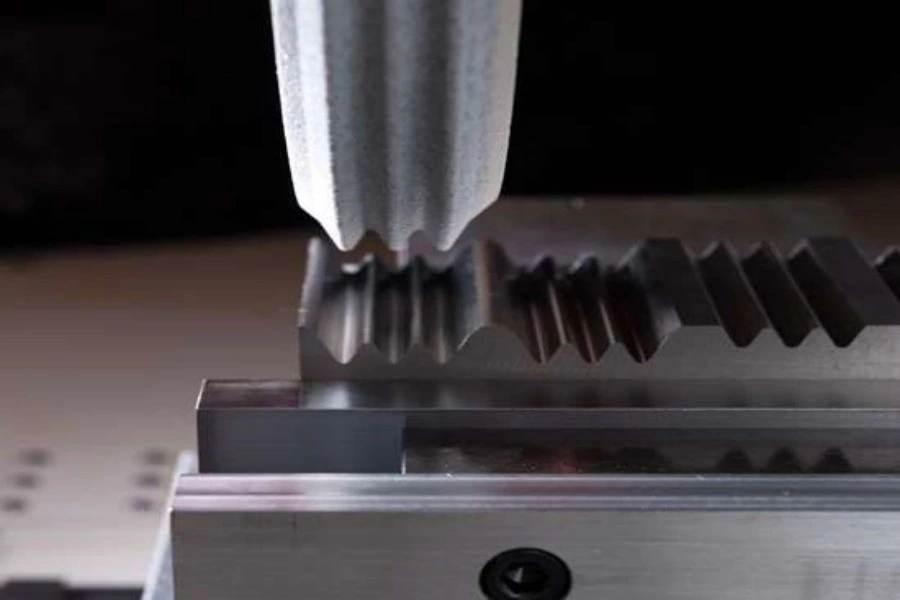

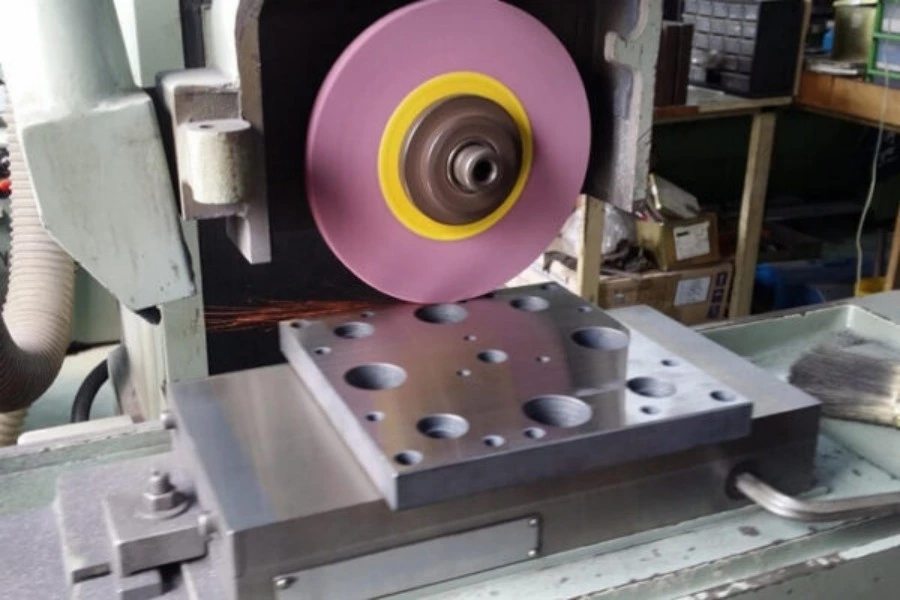

Grinding shapes flatness, alignment, and edge profiles on machine components. From ironing plate bevels to presser foot platforms and detacher bases, precision grinding ensures optimal pressure contact, movement smoothness, and system alignment.

Deburring removes small metal protrusions caused by casting, cutting, or machining. Left untreated, burrs can tear fabrics, injure users, or interfere with product fitment. Robotic deburring guarantees clean, rounded, and safe edges in even the smallest mechanical parts.

Delivers smooth surfaces on ironing plates, machine covers, and components interacting with textiles, ensuring safety and a refined look.

Used to shape pressing tools, flat surfaces, and machine interfaces requiring precise geometry and smooth glide under high-speed movement.

Applied to metal hooks, lock parts, or presser foot assemblies—eliminating sharp edges and improving component integrity for daily textile handling.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Polished and burr-free machine components protect delicate fabrics and support optimal ironing or stitching performance. Automated systems consistently deliver finishes that reduce snags, heat retention issues, or visual inconsistencies.

Key for:

Soleplates, presser components, and magnetic holders require accurate surface dimensions and edge profiles to operate effectively. Robotic grinding maintains strict tolerances with in-process feedback, eliminating variations seen in manual work.

Valuable for:

Robotic cells operate continuously with minimal operator input, handling complex profiles and part rotations with ease. This not only boosts output, but also reduces operator fatigue and long-term health risks.

Efficient for:

Surface finishing issues like uneven bevels or over-polishing can cause costly rejections. Kingstone’s force-controlled systems deliver reliable results with fewer damaged parts and greater first-pass yield.

Beneficial for:

Textile-related production often requires clean spaces with minimal dust and debris. Our enclosed grinding and polishing systems include dust extraction and filtration—making them suitable for integration into garment equipment assembly areas.

Perfect for:

Different components in clothing machinery—such as aluminum iron plates, stainless steel guides, or polymer-based presser accessories—demand unique surface treatment parameters. Automated finishing systems can be programmed for material-specific speeds, pressures, and abrasive selections, ensuring each part receives the appropriate treatment without the need for tool changes or manual intervention.

Ideal for:

• Multi-material assemblies in modern ironing or pressing units

• OEMs producing both entry-level and high-end garment equipment

• Adaptive production lines with varied part geometries and substrates

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.