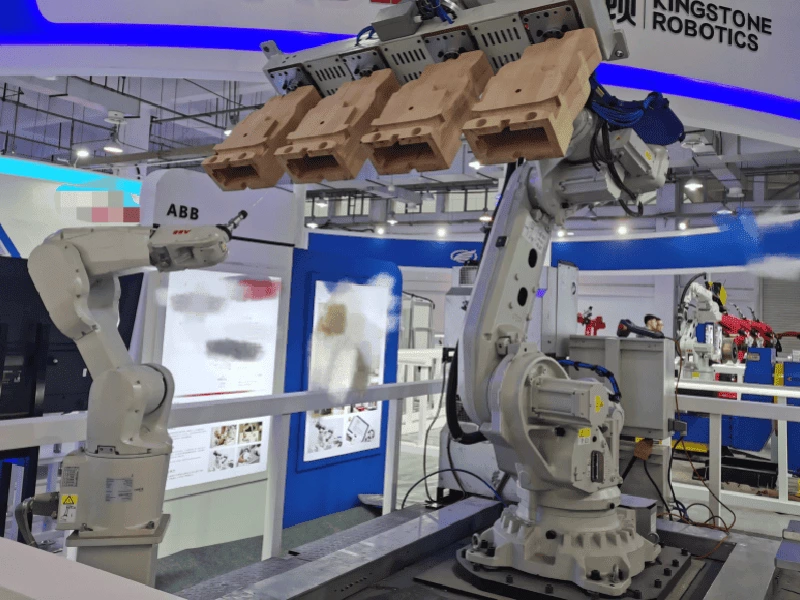

From aluminum rim wheels and bumpers to roof racks, license plate frames, engine blocks and heads, and more, Kingstone absolutely can be provides cost-effective automation solutions, that is robotic surface polishing and grinding equipment automation solutions for the automotive industry manufacturer.

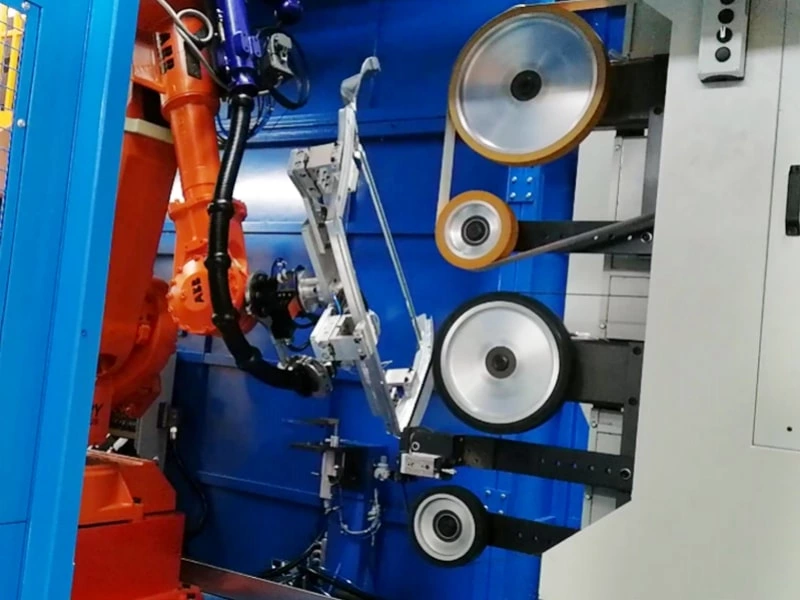

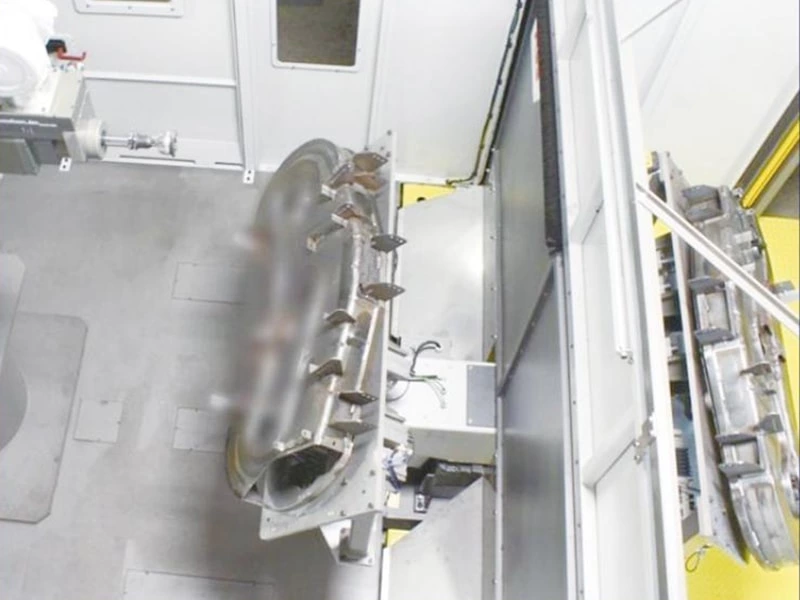

Automation solutions: Fully automatic robot flexible grinding/polishing/deburring system, including mirror polishing, cloth wheel buffing, sand belt grinding, deburring, cutting and welding and other operations.

These automation solutions help customer companies meet growing demands for precision in production and product surface treatment, as well as address health and safety issues.

Kingstone Robotics specializes in providing state-of-the-art robotic solutions tailored specifically for automotive surface treatment processes. With proprietary sanding and polishing technology, we offer fully integrated automation solutions including:

In the automotive industry, the demand for high-quality, precision-engineered components is ever-increasing. To meet these demands, manufacturers are turning to automated solutions for surface finishing processes such as polishing, grinding, and deburring. These processes are critical for ensuring the performance, safety, and aesthetics of automotive parts.

Polishing is a surface finishing process aimed at creating a smooth and shiny surface by rubbing it or using a chemical action, leaving a surface with a significant specular reflection. In automotive manufacturing, polishing enhances the aesthetic appeal and can also improve corrosion resistance.

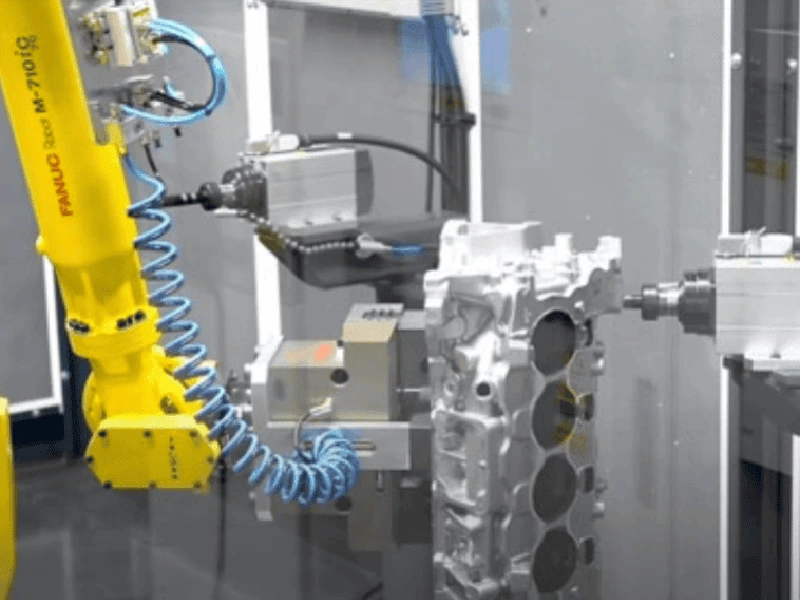

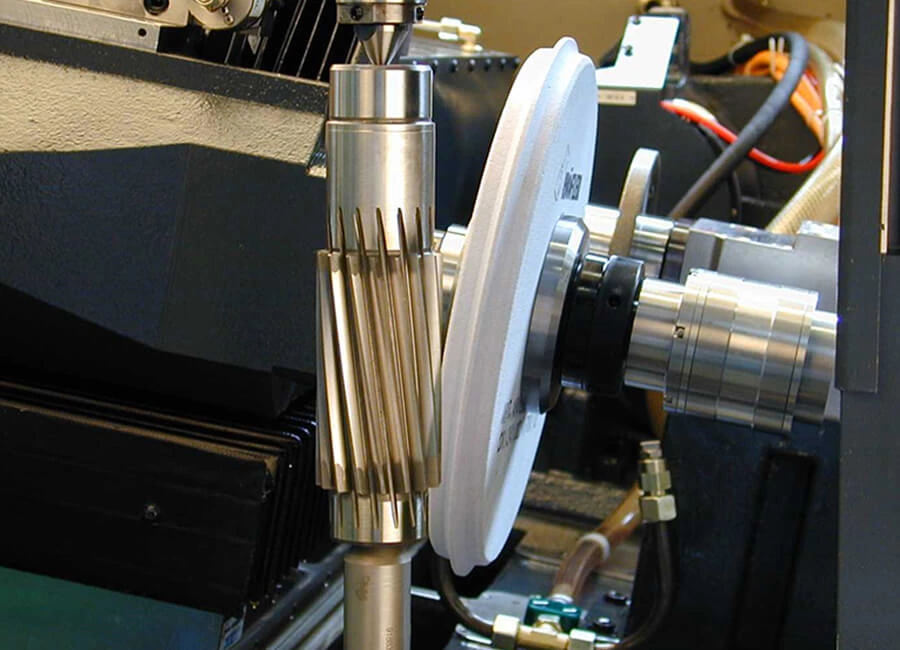

Grinding is a machining process that uses an abrasive wheel as the cutting tool. It’s employed to achieve high surface quality and precision in dimensions. In the automotive industry, grinding is used to finish components like crankshafts, camshafts, and gear shafts.

Deburring involves removing small imperfections, known as burrs, from the surface of metal parts after machining processes. These burrs can affect the performance and safety of automotive components, making deburring a crucial step in manufacturing.

Automated polishing systems use robotic arms equipped with polishing tools to achieve desired surface finishes. These systems can be programmed for various polishing patterns and pressures, ensuring consistent quality.

In automated grinding, robotic systems control the movement and pressure of grinding tools against the workpiece. Sensors and feedback mechanisms adjust parameters in real-time to maintain precision.

Automated deburring employs robotic arms with specialized tools to remove burrs from complex geometries. Vision systems can identify burr locations, allowing for targeted removal without affecting the integrity of the part.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Automated surface finishing systems deliver a uniform finish across all parts, eliminating human inconsistencies caused by fatigue, skill variation, or environmental factors. This is especially important for components requiring tight tolerances, such as:

Robots can precisely control force, angle, and speed, ensuring consistent surface roughness (Ra values) and edge profiles.

Robots work continuously without breaks, significantly boosting productivity. Automated systems can:

This allows manufacturers to meet tight deadlines and scale production without compromising quality.

Grinding and polishing automotive parts often involve high-speed rotating tools, airborne particulates, and physical strain. Automating these tasks:

This not only enhances workplace safety but also helps meet health and safety regulations such as OSHA standards.

While the initial investment in robotic systems can be significant, automation lowers long-term operating costs by:

Over time, these savings result in a lower total cost per part.

Modern automotive design trends favor complex geometries and lightweight materials (e.g., aluminum, magnesium, carbon fiber). Robotic systems:

This flexibility supports the industry’s shift toward lightweight and electric vehicle components.

Automation solutions are modular and can be tailored to production volume, part type, and finishing requirements. Whether for:

Robotic polishing and grinding systems can be scaled and integrated seamlessly into the production line.

Customized Solutions: Kingstone provides tailored deburring automation to meet diverse quality specifications for automotive wheels.

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.