With its accuracy, intelligence and cost-effectiveness, the grinding process of industrial robots has very obvious advantages, especially in the production and processing of military machinery products. It is precise and efficient, and the grinding errors can be controlled within the specified range.

Military hardware requires unmatched durability and precision, from gun barrels to helmet shells—built to perform in extreme conditions.

Kingstone Robotics offers specialized robotic systems for grinding, polishing, and finishing military components, ensuring consistent quality, reduced operator risk, and scalable production for demanding defense applications.

In defence manufacturing, surface treatment affects more than appearance—it impacts functionality, ballistic integrity, environmental resistance, and even soldier safety. Polishing improves glide and seal compatibility, grinding ensures dimensional accuracy, and deburring prevents mechanical or operational failure. Automation allows these finishing tasks to be carried out to exact specifications and repeatable standards.

Polishing is used to smooth and refine external and internal surfaces. In military equipment, polishing can reduce surface friction in moving parts, enhance corrosion resistance, and provide a finished look for presentation-grade components such as optics housing, helmet shells, or firearm exteriors.

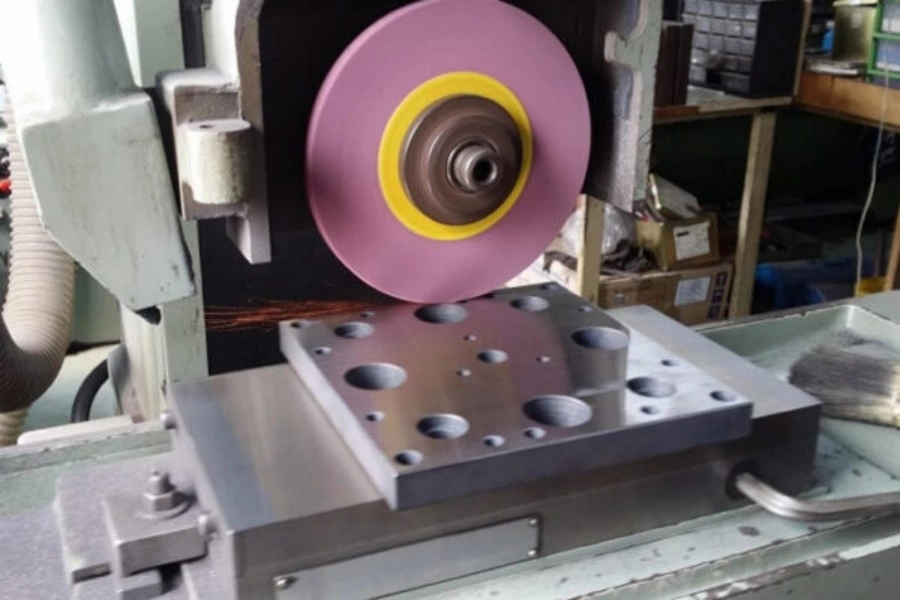

Grinding is critical in shaping, profiling, and preparing parts to meet extremely tight tolerances. In military manufacturing, this includes barrel internal diameters, mating surfaces of casings, or the planar alignment of optic and sensor modules.

Deburring eliminates sharp edges and micro-irregularities that could compromise assembly, cause wear, or become a safety hazard in high-pressure or high-heat environments. This is especially crucial in firearm components, ammunition casings, and safety hardware.

Provides smooth and durable surfaces for operational reliability and uniform appearance, especially in parts exposed to weather or combat stress.

Enables precise shaping and edge profiling of ballistic-grade materials, ensuring parts meet functional specs and dimensional tolerances.

Critical for sharp-edged components, reducing assembly issues and increasing wear resistance across a wide range of military-grade parts.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Automated finishing systems maintain repeatable tolerance and surface roughness values as required by military procurement agencies. This guarantees parts meet requirements such as NATO, MIL-STD, or ISO 9001/9100 for defence manufacturing.

Applies to:

Manual grinding and polishing of hardened or sharp military parts pose injury risks. Automation removes operators from hazardous tasks and ensures ergonomics, dust control, and tool longevity.

Ideal for:

repeatable output. Batch runs of thousands can be finished with minimal variation, while multi-SKU production can be supported with quick setup changeovers.

Supports:

Combat and tactical hardware operate in extreme temperatures, mud, salt, dust, and impact zones. Precision-ground and polished components help resist pitting, fatigue, and operational jamming. Deburred edges prevent cracking or pressure point failure.

Essential for:

Although military hardware demands high-quality materials and finishing, automation helps reduce the cost-per-unit by lowering rework, downtime, and labour. Additionally, surface-optimized parts have longer service lives, reducing MRO costs and improving lifecycle value.

Benefits:

If you’re ready, I can proceed to the next industry (e.g. Agricultural Tools, Home Appliances, Kitchenware Hardware), or help format this content for web/Elementor usage. Just let me know!

Military hardware often integrates materials like steel, titanium, ceramics, and composites within a single component or system. Automated surface finishing systems can be programmed to adapt to each material's hardness, heat sensitivity, and finishing requirements—ensuring uniform results across hybrid assemblies without damaging adjacent areas.

Applicable to:

• Advanced optics housings with aluminum-titanium combinations

• Personal protective gear with ceramic-metal fusion zones

• Multi-layered missile components or drone chassis with composite frames

Production of lenses and windows for scopes, periscopes, and other optical devices.

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.