Customers in the new energy industry use Kingstone robotic polishing equipment to complete the grinding and polishing of various new energy products. Such as metal parts in electric vehicles and solar water heaters, our automation solution is suitable for grinding large pieces and polishing curved products.

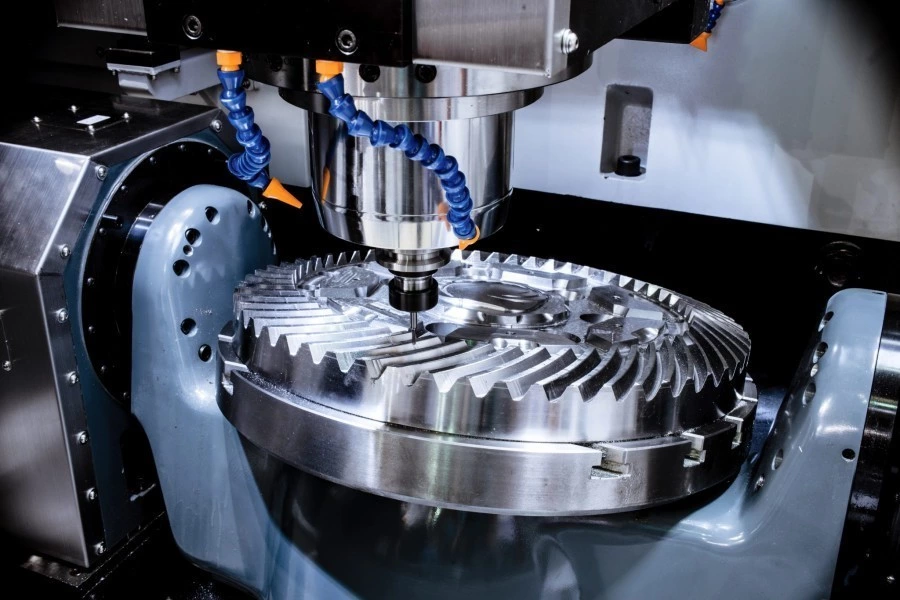

Kingstone Robotics delivers specialized robotic grinding, polishing, and deburring systems tailored for the new energy sector. Our advanced automation solutions enhance the manufacturing of components critical to electric vehicles, renewable energy systems, and energy storage technologies. By integrating precision robotics with intelligent control systems, we provide consistent, high-quality surface finishing that meets the stringent standards of the new energy industry.

The new energy industry demands components with high precision, durability, and aesthetic appeal. Automated surface finishing processes such as grinding, polishing, and deburring are essential in achieving these requirements. Kingstone Robotics’ solutions are designed to handle complex geometries and diverse materials, ensuring optimal performance and longevity of new energy products.

Polishing Automation

Enhances the appearance and corrosion resistance of charging piles and battery enclosures, ensuring consumer appeal and longevity.

Grinding Automation

Achieves precise dimensions in battery trays and base castings, critical for structural integrity and assembly compatibility.

Deburring Automation

Removes imperfections from connectors and solar brackets, improving safety and ensuring reliable electrical connections.

Enhances the appearance and corrosion resistance of charging piles and battery enclosures, ensuring consumer appeal and longevity.

Achieves precise dimensions in battery trays and base castings, critical for structural integrity and assembly compatibility.

Removes imperfections from connectors and solar brackets, improving safety and ensuring reliable electrical connections.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Automated finishing guarantees surface quality and dimensional accuracy across every part. With adaptive force control and real-time feedback, grinding and polishing remain stable on variable geometries and material hardness.

Whether for:

Our robotic cells maintain precision, even in demanding production environments.

Combining robotic arms, automatic tool changers, and coordinated motion control, our systems reduce cycle times and increase part throughput. Automation is especially beneficial in processing high-volume, heavy components where manual labor is inefficient.

Whether for:

Automation allows your line to operate at peak efficiency.

Manual surface finishing in the rail sector often involves heavy tools, hot workpieces, and hazardous dust. Our robotic systems eliminate direct operator contact, reducing risk of injury and improving air quality on the shop floor.

Whether for:

Robotic automation shields workers from high-risk processes.

Automation reduces labor dependency, scrap rates, and inspection failures. With predictive maintenance and tool life monitoring, total cost of ownership is optimized for long-term operations.

Whether for:

Automation delivers cost savings and measurable ROI.

Kingstone’s systems are designed for integration into digital production environments. Robots can interface with MES/ERP systems, provide finishing data (roughness, pass/fail rates), and adapt toolpaths via real-time sensors or vision systems.

Whether for:

Our automation solutions prepare your factory for the evolving demands of energy system manufacturing.

New energy systems often involve lightweight alloys, composite housings, and multi-material assemblies that require distinct surface treatments. Robotic finishing systems adapt force, speed, and tool type in real time—preventing delamination, overheating, or over-polishing, while ensuring consistent finishes across diverse material zones.

Ideal for:

• EV battery enclosures combining aluminum and polymer inserts

• Inverter casings with coated heat-dissipation surfaces

• Solar panel brackets requiring both weld cleanup and anodizing prep

Enables inline automation for EV chassis or battery box production

Motor base castings, inverter housing bases, energy storage unit mounts, EV subframe components

EV battery trays, cooling plate enclosures, module integration frames, hybrid vehicle cell trays

EV charging piles, commercial fast-charging units, power cabinet enclosures, urban energy kiosks

Battery connectors, high-voltage plug terminals, busbar modules, energy module interconnects

Built for 24/7 use in large-scale solar factories

Solar panel mounting brackets, single/dual-axis tracker arms, PV rail supports, ground-mount solar frame parts

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.