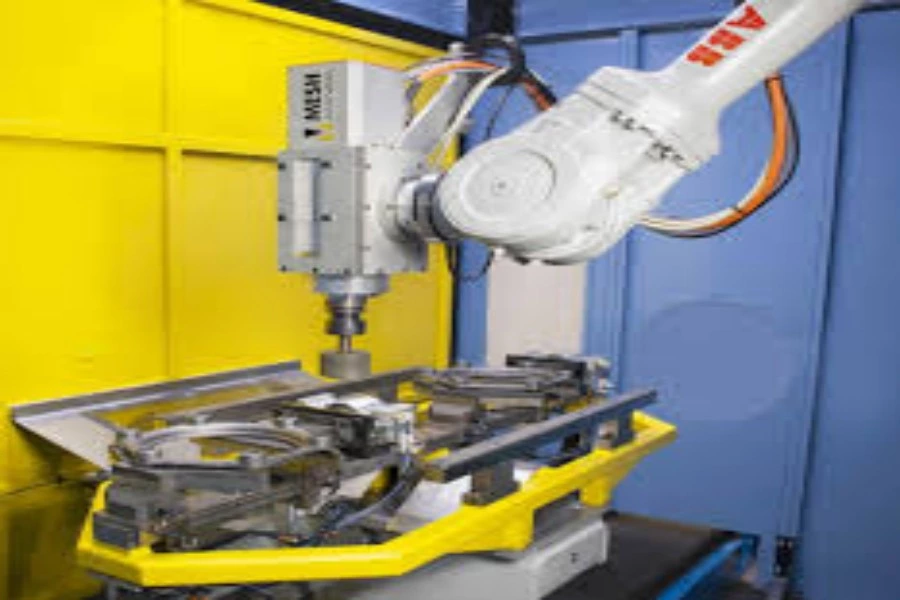

The Kingstone robotics polishing system can find the optimal knife hardware polishing solution based on different alloy materials, improving accuracy and service life and reducing polishing depth errors. At the same time, the surface effect can also be adjusted according to customer needs.

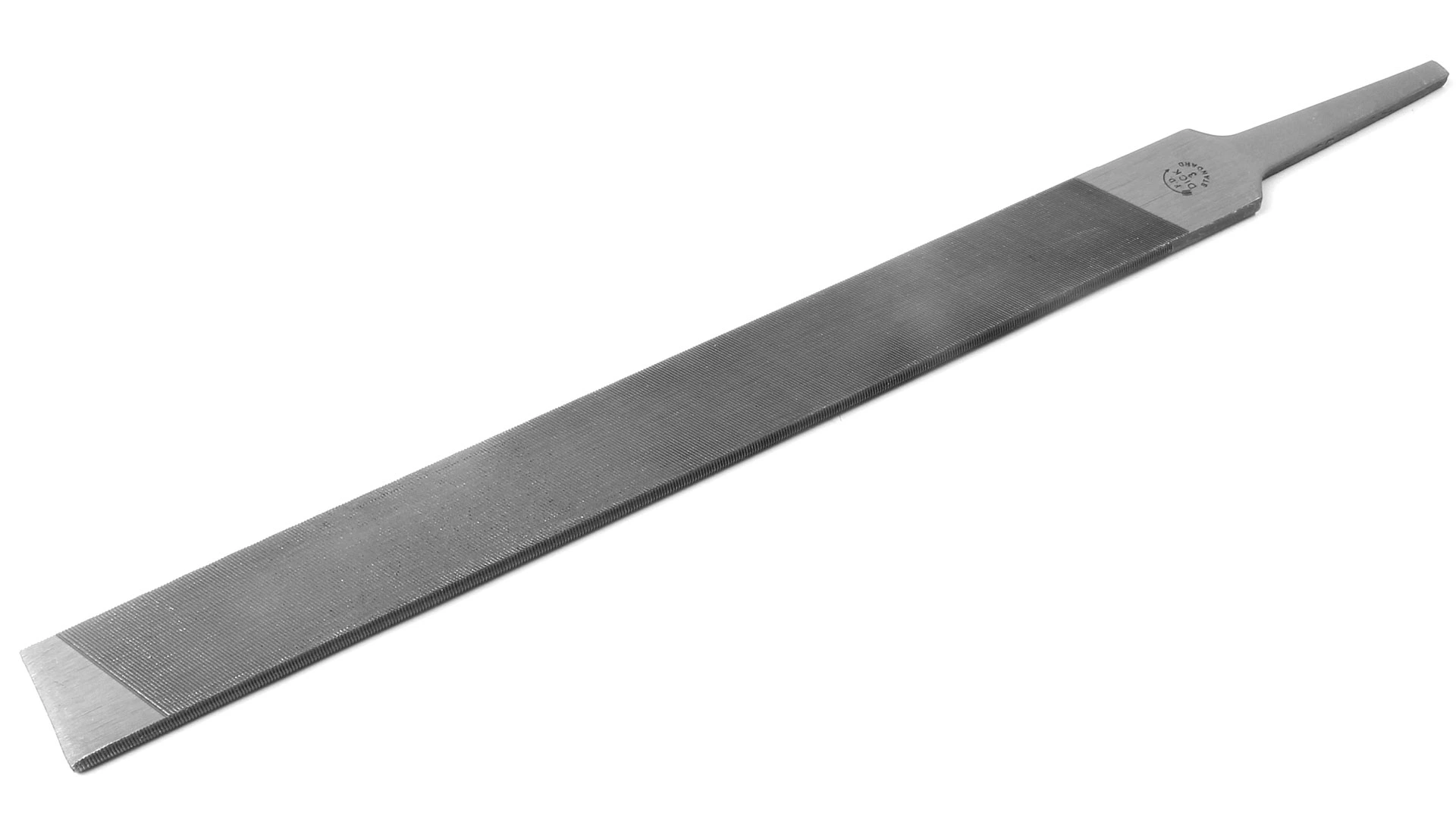

Knife hardware requires precise edge geometry, uniform finish, and lasting durability—vital for tools from utility blades to axes. Visual consistency and safety are key, especially at scale.

Kingstone Robotics delivers robotic grinding and finishing systems for knives of all shapes and materials, ensuring sharpness, accuracy, and high-volume efficiency.

Knife hardware finishing requires both functional and aesthetic precision. Whether for a kitchen knife, axe, or gardening hoe, grinding defines the blade’s performance; polishing refines it; deburring ensures usability and safety. Automation ensures that all these aspects are delivered with consistency, scale, and reduced human exposure to dangerous tasks.

Polishing enhances both the look and feel of knife hardware. While not always required for functional tools, polishing improves corrosion resistance, blade glide, and perceived product quality. It’s often used on axes, putty knives, and decorative knife types to smoothen surfaces and reduce material drag.

Grinding defines the blade’s profile, angle, and sharpness. It’s a subtractive process using abrasive belts or wheels to achieve the edge geometry and surface flatness. Different blade types require different angles and edge depths—automated grinding guarantees this level of accuracy.

Deburring removes tiny metal projections or “burrs” left by earlier machining steps. These burrs can pose safety risks, interfere with packaging, or degrade cutting precision. Robotic deburring ensures every edge is cleaned and safe before sharpening or coating.

Applies smooth finishes to tool surfaces, enhancing glide and rust resistance. Common in putty knives, stainless utility blades, and premium axes.

Forms sharp, even edges on symmetrical or compound curved tools like garden scissors, knives, and hoes.

Removes irregularities and edge projections that could cause injury or reduce blade performance—vital in tools with ergonomic applications.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Sharpness is only effective when consistently reproduced. Robotic grinding systems use force sensors and path control to ensure identical edge angles and material removal across large batches.

Best for:

Manual grinding risks over-removal and blade warping. Automation maintains strict depth control, adaptive speed, and even heat management—preserving materials and extending tool life.

Critical for:

Knife finishing tasks involve sharp edges, heavy vibration, dust, and high-speed wheels—posing significant injury risks. Robotic automation removes workers from the high-risk zone while maintaining speed and consistency.

Beneficial for:

Kingstone’s robotic systems support rapid changeovers and CAD-driven path programming. This allows quick adaptation to different blade types or seasonal product mixes without compromising finish quality.

Ideal for:

Our robotic cells can integrate into existing production environments—working alongside CNC blanking, heat treatment, and coating stations. This helps manufacturers automate edge finishing without fully rebuilding their infrastructure.

Enables:

Beyond function, knives must meet strict visual standards for retail presentation and brand recognition. Automated polishing systems ensure uniform satin, mirror, or brushed finishes across batches—eliminating streaks, discoloration, or uneven textures often found in manual work.

Valuable for:

• Premium kitchen knives with polished spine and bevels

• Branded collector or gift sets requiring flawless appearance

• Private-label cutlery with strict cosmetic QA standards

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.