In today’s precision-driven manufacturing landscape, robotic surface finishing systems must go beyond automation — they must be intelligent, adaptable, and data-validated. Kingstone Robotics delivers on that demand with an upgraded system architecture that outperforms traditional robot grinding solutions.

Engineered for industrial consistency, flexibility, and process control:

Real-time feedback enables precise control of grinding force, speed, and path, ensuring stable output quality.

Full-surface contour scanning enables dynamic adjustment, ideal for irregular or multi-angled parts.

Supports multi-dimensional process configuration—force, direction, contact area, speed, etc.—based on workpiece characteristics.

Data-driven consumable selection ensures repeatability, cost-efficiency, and optimal surface

Limitations commonly found in the industry:

Programs run without real-time feedback, leading to inconsistencies in surface finish.

Only point-based detection; unable to handle complex surfaces with dynamic feedback.

Parameters are fixed for a specific scenario, reducing adaptability to mixed materials or varied part geometries.

Relies on operator experience; results vary and lack repeatability.

Traditional open-loop systems lack the adaptability to respond to real-time variations, often resulting in inconsistent finishes. Kingstone’s closed-loop control systems utilize real-time feedback to adjust grinding force and tool paths dynamically, ensuring uniform surface quality across all components. This approach minimizes defects and reduces the need for rework, leading to significant cost savings and improved product quality.

Standard 2D inspection methods fall short in detecting subtle surface irregularities, especially on complex geometries. Kingstone employs advanced 3D vision systems that capture detailed surface profiles, enabling precise detection of imperfections and ensuring consistent quality. This technology is particularly beneficial for components with intricate designs, such as engine blocks and gearbox housings.

Variability in manual processes can lead to inconsistencies in product quality. Kingstone’s standardized process database ensures that each operation adheres to predefined parameters, maintaining consistency across all production batches. This standardization streamlines operations, reduces training requirements, and facilitates quicker adaptation to new projects or product lines .

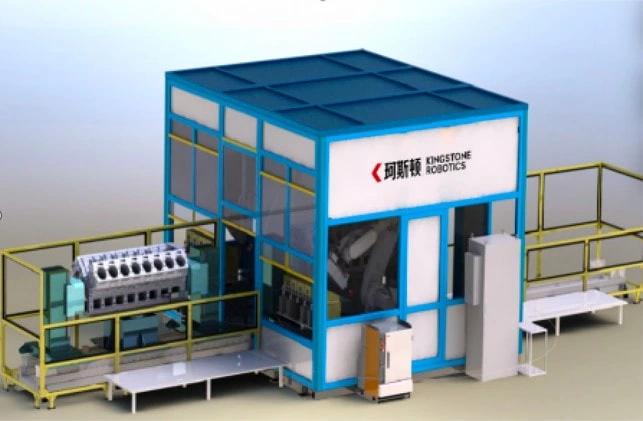

Heavy-duty robotic solution for engine blocks, structural castings, and oversized components

Core Technologies:

Which Can Solve :

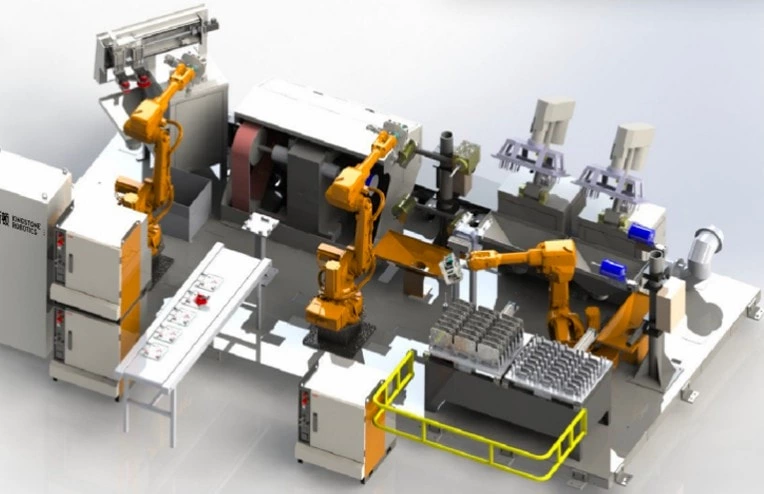

Flexible robotic unit designed for mid-sized cast parts with complex geometries

Core Technologies:

Key Value:

Multi-station solutions for small parts, surface finishing, and high-volume production

Core Technologies:

Key Value:

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.