The range of processes includes robotic grinding, deburring, and polishing, from deburring escalator parts to polishing automatic doors.

Kingstone provides great innovative and cost-effective robotic grinding systems.

Robot polishing machining processes reduce the need for manual labor and the difficulty of polishing hard steel and aluminum parts.

Kingstone Robotics is a trusted provider of robotic grinding, polishing, and deburring systems engineered for the rail transit industry. Leveraging proprietary automation technology and precision robotic integration, we help manufacturers improve part consistency, reduce manual labor, and enhance the durability and safety of railway components. Our systems are purpose-built to meet the high standards of railway equipment manufacturing and maintenance.

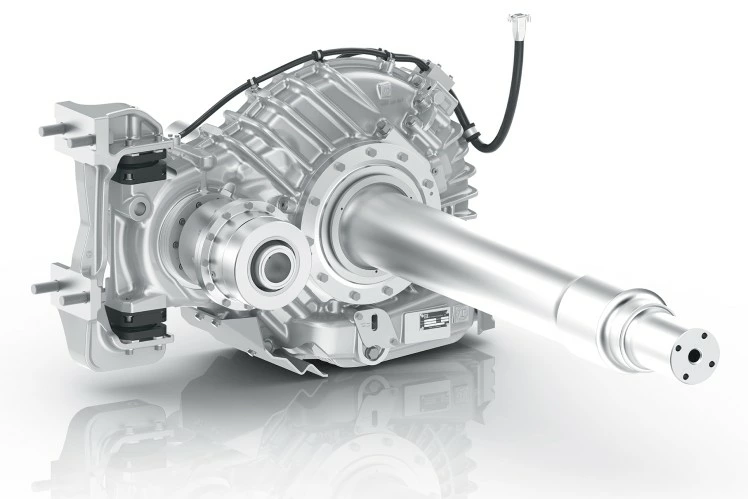

The rail transit industry demands large, rugged components with tight tolerances and long service lives. Automated polishing, grinding, and deburring play a critical role in achieving these goals by ensuring high-quality surface finishing across structural, drivetrain, and mechanical subsystems. Kingstone’s robotic systems are optimized for components like bogies, connectors, bearings, and housings—delivering consistent results even on complex surfaces.

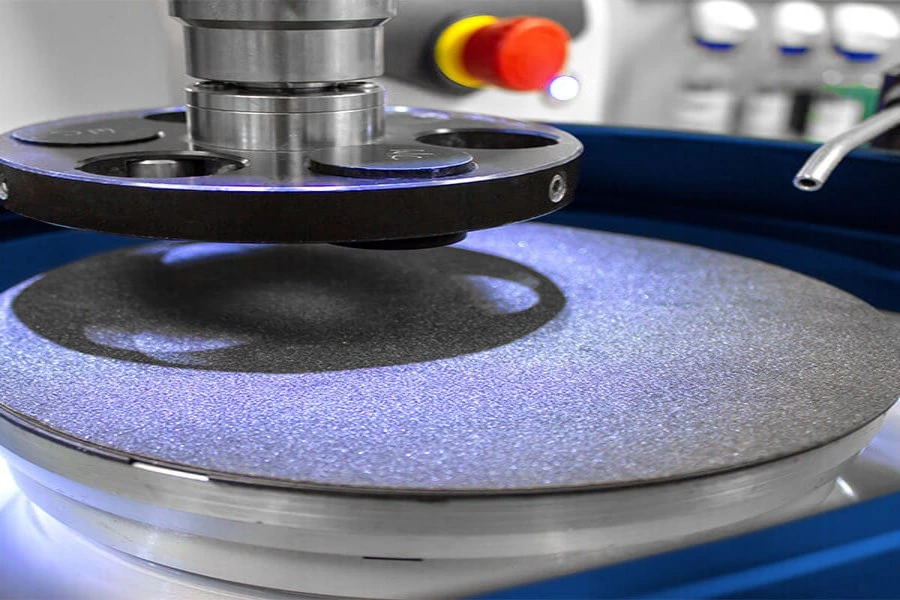

Polishing is a mechanical finishing process that reduces surface roughness, enhances aesthetics, and improves corrosion resistance. In the rail industry, polishing is especially important for stainless-steel covers, brackets, and external-facing structures to ensure smooth visual lines and environmental durability.

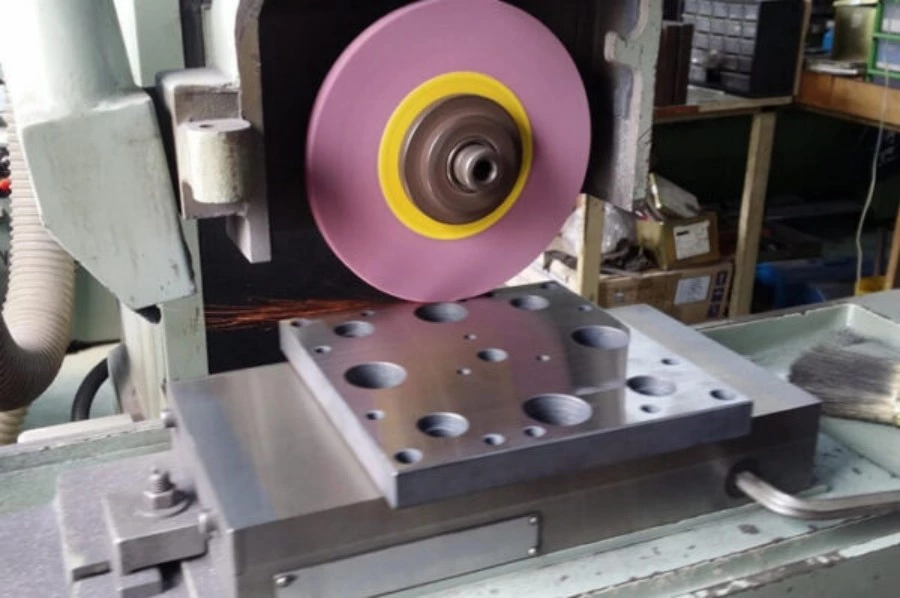

Grinding is a precision material removal process that produces flat, round, or contoured surfaces with tight tolerances. It is widely used in rail applications for preparing high-load-bearing parts such as axles, gearbox housings, and coupling elements. Automated grinding ensures dimensional control across large, heavy parts with consistent repeatability.

Deburring removes sharp edges and residual burrs left after casting, machining, or welding. In railway component assembly, burrs can impair fitment, create safety hazards, or reduce fatigue life. Automated deburring ensures clean edges, smooth mating surfaces, and long-term structural integrity.

Applied to outer covers, housings, and welded joints to improve appearance and environmental resistance. Robotic polishing achieves consistent surface textures and eliminates manual variability.

Used for precision finishing of structural parts like shafts, bars, and brackets. Ensures geometry, balance, and surface quality for high-load rail systems.

Removes weld spatter, casting flash, and machining burrs from safety-critical components. Supports clean assembly and extends fatigue life under dynamic loads.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Automated finishing guarantees surface quality and dimensional accuracy across every part. With adaptive force control and real-time feedback, grinding and polishing remain stable on variable geometries and material hardness.

Whether for:

Our robotic cells maintain precision, even in demanding production environments.

Combining robotic arms, automatic tool changers, and coordinated motion control, our systems reduce cycle times and increase part throughput. Automation is especially beneficial in processing high-volume, heavy components where manual labor is inefficient.

Whether for:

Automation allows your line to operate at peak efficiency.

Manual surface finishing in the rail sector often involves heavy tools, hot workpieces, and hazardous dust. Our robotic systems eliminate direct operator contact, reducing risk of injury and improving air quality on the shop floor.

Whether for:

Robotic automation shields workers from high-risk processes.

Automation reduces labor dependency, scrap rates, and inspection failures. With predictive maintenance and tool life monitoring, total cost of ownership is optimized for long-term operations.

Whether for:

Automation delivers cost savings and measurable ROI.

Rail components—such as bogies, couplers, and drive housings—often feature large dimensions, multi-surface transitions, and hard-to-reach contours. Robotic systems equipped with extended-reach arms and multi-axis flexibility ensure uniform surface quality across every face, angle, and recess—something manual processes struggle to achieve at scale.

Applicable to:

• Oversized gearbox casings with internal cavities

• Welded bogie frames requiring uniform deburring

• Multi-axis surface prep before painting or coating

Kingstone’s robotic surface finishing systems are built to integrate with upstream and downstream operations, including robotic welding, CNC machining, NDT, and coating. With programmable logic, digital traceability, and MES/ERP compatibility, they support rail OEMs and MRO facilities in building fully automated and auditable production lines.

Ideal for:

• Tier-1 rail suppliers embracing Industry 4.0 principles

• Smart factories needing cross-process visibility

• MRO operations standardizing surface repair and refinishing routines

Axle bearing journals, wheel hub seats, bogie shaft ends, inner bearing shells

Transmission box covers, drive unit casings, differential gear housing, reducer enclosures

Mounting brackets, sensor housings, structural link plates, electrical connectors

Traction link rods, anti-roll bars, suspension control arms, stabilizer bars

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.