Medical artificial joints, surgical knives and other medical equipment, strict requirements for product surface polishing. But Kingstone robot application experts have rich experience, we can develop fully automatic grinding, polishing and finishing solutions for customers. Such as human joint bone stem (titanium alloy artificial joint).

Kingstone Robotics delivers specialized robotic polishing, grinding, and deburring solutions tailored for the stringent demands of the medical industry. Our systems are engineered to meet the highest standards of cleanliness, surface quality, and dimensional precision required in surgical tools, orthopedic implants, and prosthetic devices. Through adaptive robotic control and real-time feedback systems, we help manufacturers scale production while maintaining flawless repeatability across every critical component.

Precision surface treatment plays a vital role in the medical industry. Whether for implants inserted into the human body, surgical tools used in sterile operating environments, or prosthetics that interact with skin and muscle, surface quality directly affects product performance, safety, and regulatory compliance. Robotic automation is now a cornerstone in the production of these components, replacing manual variability with clean, repeatable precision.

Polishing is a fine surface finishing process that removes microscopic imperfections and produces smooth, often mirror-like surfaces. In medical manufacturing, it is crucial for reducing the risk of bacterial adhesion, minimizing friction in joint replacements, and achieving the aesthetic quality required for external prosthetics. Stainless steel, titanium alloys, and cobalt-chrome components are typically polished to Ra < 0.2 µm.

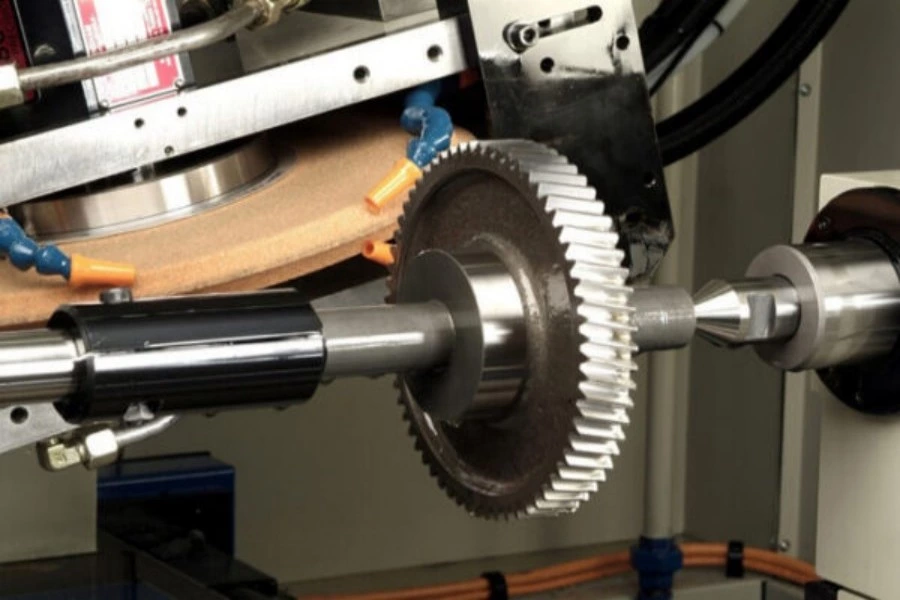

Grinding is a subtractive machining process that uses abrasive tools to achieve tight dimensional tolerances. It is essential for shaping prosthetic components, orthopedic bone plates, and joint replacements with high mechanical fit and surface geometry. Automated grinding ensures repeatability in parts that must integrate seamlessly into the human body.

Deburring removes small metal fragments and sharp edges left after machining or casting. These imperfections can cause tissue damage, improper fitment, or contamination in medical applications. Robotic deburring ensures that every edge is safe, clean, and conforming to standards such as ISO 13485 and ASTM F86.

Used in surgical implants and forceps to achieve uniform mirror finishes that meet clinical hygiene standards and reduce bacterial colonization.

Essential for orthopedic plates, prosthetic interfaces, and implant features where precise geometry is critical to surgical fit and biomechanical function.

Applied to surgical tool edges, bone screws, and titanium implants to eliminate micro-burrs that may compromise sterility or cause tissue abrasion.

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

Robotic systems deliver repeatable finishes that meet MDR, FDA, and ISO 13485 standards for surface roughness, cleanliness, and biocompatibility. Through real-time force control and in-process verification, we ensure every part meets compliance—even under high-volume output.

Whether you’re manufacturing:

Automation guarantees clinical-grade quality across every batch.

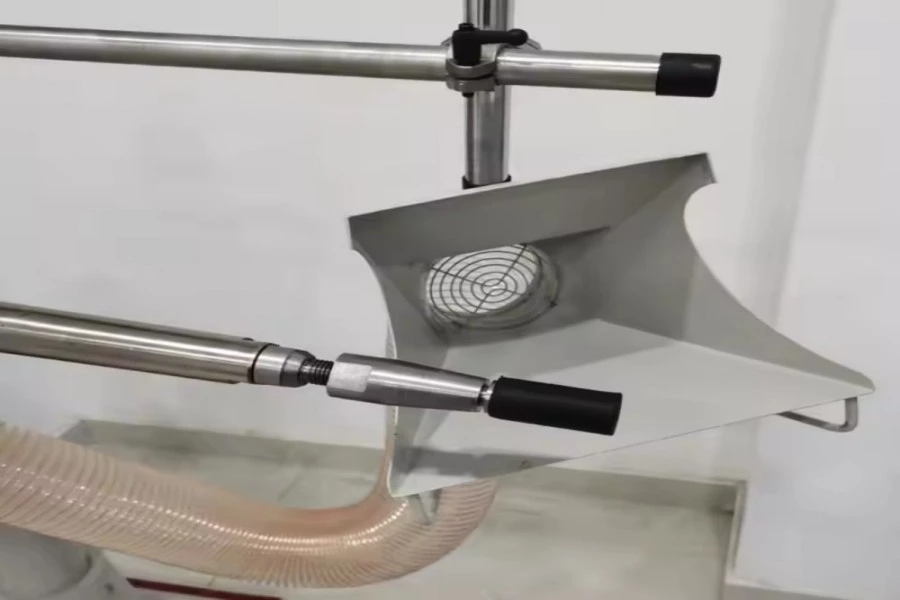

In medical device production, quality must never be sacrificed for speed. Kingstone’s robotic systems combine multiple finishing processes (grinding, polishing, deburring) into a single automated cell. With cleanroom-compatible enclosures and HEPA filtration, they maintain surgical-grade cleanliness even at industrial scale.

Use cases include:

Manual polishing and grinding create risks of particulate contamination, heat exposure, repetitive motion injuries, and sharp tool handling. Robotics removes humans from the high-risk zone, reduces contamination potential, and ensures ergonomic, consistent workflows.

Especially relevant for:

Medical parts are often high-value, low-tolerance items—errors are costly. Automation minimizes scrap through accurate force sensing, auto-correction, and post-process inspection modules. You save not just time, but high-value material.

Applicable for:

Titanium knee replacements

Cobalt-chrome hip stems

Custom 3D-printed prosthetics

Kingstone’s robotic finishing systems integrate seamlessly into MES, SPC, and traceability platforms, providing finishing reports, surface roughness data, and tool wear analytics. That’s critical for audits, certifications, and lean medical production.

Supports:

Medical components often feature intricate contours, internal recesses, and miniature features where finishing precision is critical—especially in implants or microsurgical tools. Robotic systems with multi-axis kinematics and micron-level path control can access and finish complex shapes that are difficult, inconsistent, or impossible to handle manually.

Ideal for:

• Porous-surfaced implants requiring selective polishing

• Laparoscopic tools with slender shafts and sharp curves

• Dental instruments with micro-serrations or recessed grip zones

Automated polishing of joint surfaces to achieve required smoothness for optimal articulation.

Backed by decades of experience and partnerships with leading global brands.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.