Robotics vs. AI: Key Differences for Smarter Automation

In today's competitive landscape, "Robotics" and "Artificial Intelligence" (AI) are key drivers of business efficiency and innovation. However, the terms are often used interchangeably, creating confusion that can be a barrier to making effective investment decisions. For business leaders, understanding the precise difference isn't just an academic exercise—it's essential for identifying the right tools to solve your operational challenges.

This guide will provide a clear, practical breakdown of what these technologies are, how they differ, and how their strategic combination—intelligent automation—delivers real-world value.

The Core of Robotics: A Physical Tool for a Physical World

At its core, robotics is an engineering discipline focused on designing and building physical machines to perform tasks in the real world. The keyword is physical. A robot is a tangible asset, a piece of equipment designed to interact with its environment to move, lift, weld, assemble, or transport objects.

Think of robotics as the ultimate evolution of the tool. Every robot consists of:

- A Mechanical Structure: The arms, joints, and chassis that provide the physical capabilities.

- Sensors: Components like cameras or lasers that gather specific, measurable data from the environment.

- Actuators: The motors and drives that execute a command and create physical motion.

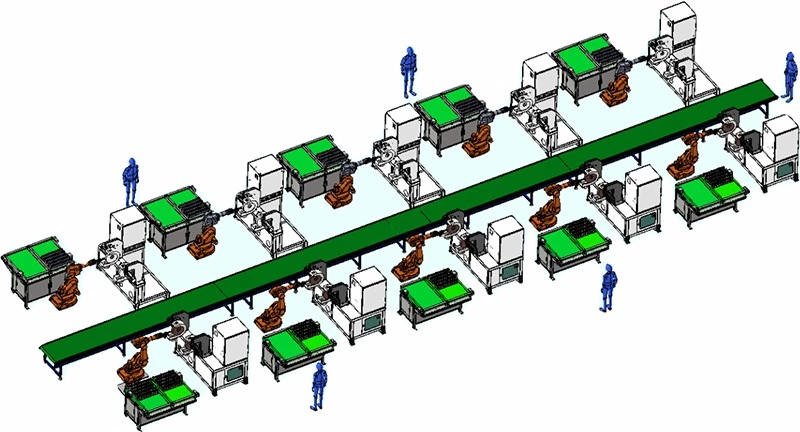

Examples are the backbone of modern industry: the CNC machine loading arm, the palletizing robot at the end of a production line, or the fleet of Autonomous Mobile Robots (AMRs) moving goods across a warehouse floor. They are all physical machines built for action.

The Core of AI: Enabling Systems to Make Smarter Decisions

If robotics is the physical tool, artificial intelligence is the decision-making software. AI is a field of computer science that enables a system to process information, recognize patterns, and automate complex decisions that would typically require a human operator.

Forget the science fiction. In a business context, AI is not about creating a "thinking machine"; it's about applying advanced data processing to achieve a better outcome. AI excels at:

- Analyzing vast datasets to identify trends or anomalies.

- Making predictions based on historical performance.

- Optimizing complex processes with many variables.

You already use AI-powered software in your business operations, such as in ERP systems that forecast demand or in CRM software that analyzes sales data. These are practical, disembodied tools that use data to drive smarter business decisions.

The Key Difference: The Tool vs. The Control System

The "Body vs. Brain" analogy is popular, but for a B2B context, it’s more useful to think of it as the tool versus the control system.

- Robotics provides the physical tool capable of performing a job.

- Artificial Intelligence provides an advanced control system that can direct that tool with greater flexibility and adaptability.

A robot can function perfectly with a simple control system (traditional automation), and an AI control system can run without a robot (software applications). The strategic question is determining which level of control your operation requires.

Not All Robots Need AI: The Power of Fixed Automation

A critical point for any operations manager is that most industrial robots do not use AI. The workhorses of manufacturing are pre-programmed robots engaged in fixed automation.

These machines are programmed to execute a precise, unchanging sequence of actions. They are incredibly fast, reliable, and deliver a massive ROI for high-volume, low-variability tasks. They excel at repetitive work, but they are inflexible. If a part on the conveyor belt is misaligned, a pre-programmed robot will likely fail the task because its simple control system cannot adapt. It’s a powerful tool, but one that follows a fixed script.

AI-Powered Software: Intelligence Beyond the Factory Floor

Just as robots don’t always need AI, powerful AI applications often have no physical form. These AI-driven software tools are becoming essential for optimizing business processes from end to end:

- Supply Chain Management: AI systems analyze global logistics data to predict shipping delays and re-route freight proactively.

- Predictive Maintenance: AI algorithms monitor data from machinery sensors to predict when a part is likely to fail, allowing maintenance to be scheduled before a costly breakdown occurs.

- Business Intelligence: AI tools sift through market data and internal KPIs to provide actionable insights for strategic planning.

These applications highlight that AI’s primary value is in processing data to enable better, faster decision-making.

The Synergy: Creating Intelligent Automation

The real competitive advantage emerges when you integrate these two technologies. When you equip a robotic tool with an AI-powered control system, you create intelligent automation. This combination elevates a robot from a single-task machine to a flexible asset that can handle variability and complexity.

This isn’t about making robots "smarter" for its own sake; it’s about giving them the capability to solve more complex business problems.

Practical AI Capabilities for Modern Robotics

Integrating AI gives robots a set of powerful, practical capabilities that directly translate to operational benefits.

- Advanced Vision Systems: This is AI-powered quality control. A camera integrated with AI can identify products, read barcodes, and detect subtle defects or cosmetic flaws far more reliably than the human eye, 24/7. This is a core technology for reducing error rates.

- Adaptive Programming: This capability, often using machine learning, allows a robot to adapt to variations. It can adjust its grip based on an object's size, or modify its welding path for a new part, all without needing a technician to reprogram it. This is the key to achieving flexible manufacturing.

- Dynamic Path Planning: In logistics and warehousing, AI allows AMRs to navigate a busy, unpredictable environment. Instead of following a fixed magnetic strip on the floor, they can perceive their surroundings and calculate the most efficient path in real-time, working safely alongside people and other equipment.

Real-World Applications Delivering Real-World ROI

The fusion of AI and robotics is not a future trend; it is actively delivering a return on investment today.

- Flexible Manufacturing: AI-guided robots can switch between different product assemblies on the fly, making small-batch, customized production profitable.

- "Lights-Out" Warehousing: Intelligent robots can manage entire warehouse operations—from inbound receiving to outbound order fulfillment—autonomously, increasing throughput and accuracy.

- Data-Driven Agriculture: As detailed by organizations like the Association for Advancing Automation (A3), robots with AI can identify crop health issues or harvest selectively, maximizing yield and resource efficiency.

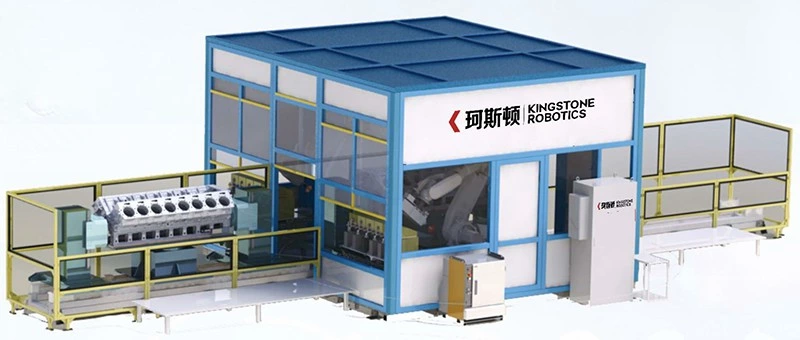

The Kingstone Robotics Perspective: Practical Solutions for Your Business

At Kingstone Robotics, we specialize in implementing practical robotic solutions enhanced with the right level of intelligence. We know that our clients aren't buying technology for its own sake; they are investing in solutions to increase throughput, improve quality, and lower operational costs.

Our process starts with your operational goals. We analyze your workflow to determine where automation can deliver the highest impact. For some, a simple, pre-programmed robotic cell is the most robust and cost-effective solution. For others facing product variability or complex inspection needs, we design and integrate systems with AI-powered vision and adaptive controls. Our focus is always on delivering a reliable, justifiable solution that solves your specific challenge and provides a clear return on investment.

The Future of Industrial Automation

Looking ahead, the integration of robotics and AI will become more seamless and accessible. The trend is moving towards systems that are easier to deploy and manage, giving businesses more control over their automation. We can expect to see more user-friendly interfaces for "teaching" robots new tasks and more built-in data analytics to help managers optimize their robotic assets.

The future isn’t about replacing workers with intelligent robots; it’s about equipping your team with better tools to do more valuable work.

Frequently Asked Questions (FAQ)

Q: Does my operation need an AI-powered robot?

A: Not always. For highly repetitive, high-volume tasks with little variation, a traditional pre-programmed robot is often the most reliable and cost-effective choice. AI becomes essential when your process involves variability, complex inspection, or decision-making.

Q: Is AI or robotics a better investment?

A: This depends entirely on your business bottleneck. If your challenge is a physical task (e.g., loading/unloading, assembly), your focus should be on robotics. If your challenge is data-driven (e.g., forecasting, quality analysis, process optimization), AI software is the answer. Often, the best investment is a combination of both.

Q: How complex is it to manage a robot with AI?

A: Modern systems are designed to be far more user-friendly than in the past. While the underlying technology is complex, the goal of a good integrator like Kingstone Robotics is to provide you with a system that has a simple interface and provides clear, actionable data, minimizing the burden on your team.