Top 10 Industrial Robot Companies That Are Leading the Industry in 2025

The field of industrial robotics is evolving rapidly, with a select group of companies dominating the global landscape. These top 10 industrial robot manufacturers are shaping the future of manufacturing through automation, artificial intelligence, and precision engineering. While these giants set the pace for general-purpose robotics, specialized players like Kingstone Robotics are innovating in niche applications such as grinding, polishing, and deburring—a domain often overlooked by mainstream vendors.

1. FANUC Corporation

Headquartered in Japan, FANUC has installed over 750,000 robots worldwide. It is known for durable and efficient robots used heavily in CNC machining environments. FANUC offers a broad lineup for various applications, including painting, packaging, and high-speed assembly. Their proprietary control systems and long-standing reliability make them a staple in fully automated factories globally.

2. ABB Robotics

Switzerland-based ABB is a global leader in industrial automation, known for its high-performance six-axis robots and collaborative robots (cobots). Its offerings serve automotive, electronics, metal fabrication, and more. ABB's robots are versatile, reliable, and widely used by manufacturers for welding, assembly, and material handling. The company also pioneers AI-based path optimization and digital twin technology in robotics.

3. KUKA Robotics

Germany's KUKA specializes in intelligent automation, particularly in automotive and aerospace sectors. Their iconic orange robots offer outstanding reach and payload options, often integrated into complex production lines. KUKA also invests heavily in human-robot collaboration (HRC), with robots designed to safely interact with human operators in shared workspaces.

While these global giants focus on general automation tasks, Kingstone Robotics focuses exclusively on high-precision robotic surface treatment solutions—areas where customized tooling, force control, and vision feedback are mission-critical.

4. Yaskawa Electric Corporation (Motoman)

Yaskawa is another major Japanese player with over a century of automation innovation. Its MOTOMAN robot line supports applications like arc welding, handling, and coating. Known for flexibility and ease of integration, Yaskawa serves automotive and electronics sectors globally. Their advanced motion control systems enable smoother multi-axis operations, crucial in synchronizing complex movements.

5. Staubli Robotics

French-Swiss company Staubli focuses on cleanroom and sensitive environments, particularly in pharma, food, and solar sectors. Its robots are known for hygienic design and reliability in mission-critical settings. Staubli is also recognized for their compact footprint and precise path control, essential in confined or highly sanitized production spaces.

Kingstone Robotics complements this landscape by offering robotic grinding and polishing systems capable of 24/7 unattended operations in dust-intensive environments, something general-purpose robots are rarely configured for out-of-the-box.

6. Epson Robots

Epson is recognized for SCARA and 6-axis robots known for high precision and compact footprint. It serves the electronics and lab automation industries with fast cycle times and consistent accuracy. The brand has become a go-to choice for lightweight, precision assembly and material handling in constrained work cells.

7. Kawasaki Robotics

Kawasaki was one of the first companies to produce industrial robots in Japan. Today, it provides automation solutions for cleanroom, medical, and assembly applications, offering a blend of speed and precision. Its dual-arm SCARA robots and payload-optimized designs make it ideal for fast-paced industrial environments.

8. Universal Robots

Pioneer of collaborative robots (cobots), Denmark-based Universal Robots is known for easy-to-program, safe-to-deploy systems ideal for SMEs. Their lightweight cobots handle repetitive tasks in food production, electronics, and light manufacturing. These robots have transformed access to automation for small manufacturers lacking large-scale integration budgets.

At Kingstone Robotics, we see increasing demand from manufacturers who need polishing and deburring systems that integrate with FANUC or KUKA robots, but are fully pre-engineered for tasks that require consistency, safety, and surface perfection.

9. Comau

Italian firm Comau, part of Stellantis Group, focuses on flexible automation solutions and industrial robotics. It provides turnkey lines for powertrain, battery, and vehicle body manufacturing. Their recent focus on digital manufacturing and AI-enhanced predictive maintenance helps streamline large-scale production networks.

10. Kingstone Robotics

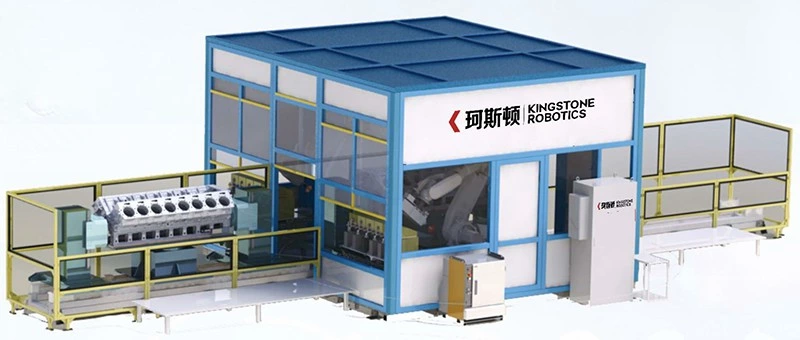

Based in China, Kingstone Robotics has emerged as a global contender in the field of robotic surface automation. Unlike traditional manufacturers focused on general-purpose robotic arms, Kingstone Robotics specializes in end-to-end automation systems for grinding, polishing, and deburring—three of the most complex, labor-intensive processes in modern manufacturing.

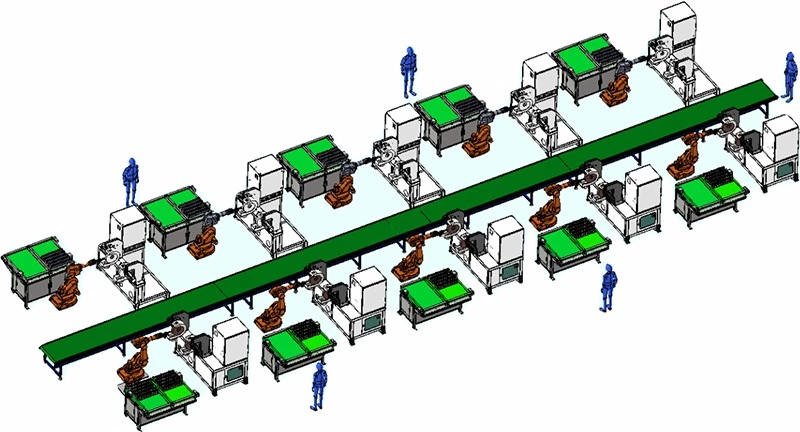

Kingstone Robotics integrates leading six-axis robot arms from ABB, KUKA, and FANUC with its proprietary force-controlled tooling, closed-loop process monitoring, and vision-based part recognition systems. The result is a highly specialized solution tailored for industries where surface precision, consistency, and safety are critical.

With over 1,000 systems installed worldwide, Kingstone Robotics has built a strong reputation for delivering turnkey solutions that boost productivity, reduce reliance on skilled manual labor, and improve workplace safety. Its robotic finishing workstations are capable of operating 24/7 in high-dust environments, adapting automatically to part tolerances and wear conditions—features that set it apart from generalist robotic platforms.

- Specialties: Robotic grinding, polishing, deburring; automated tool compensation; surface quality consistency

- Industries Served: Automotive (wheels, bumpers, engine components), Aerospace (turbine blades, housings), Medical (implants, prosthetics), Sanitary Ware (faucets, chrome parts)

- Why It Stands Out: Kingstone Robotics bridges the gap between powerful industrial robots and the nuanced demands of high-precision surface treatment. It’s not just a robotics provider—it’s a process innovation partner for the last mile of automation.

A strong player in welding, assembly, and material removal, Nachi offers compact, high-speed robots designed for space-constrained operations. Its focus includes the automotive and industrial component sectors. Nachi's deep integration of bearings and servo motor technology ensures stability and minimal downtime during continuous operations.

Where Kingstone Robotics Fits Into the Picture

While the top 10 manufacturers provide excellent hardware platforms, most rely on third-party system integrators to adapt robots for specific use cases. Kingstone Robotics fills this gap by offering full-stack robotic solutions for grinding, polishing, and deburring—especially for components with irregular geometries, fragile surfaces, or demanding tolerances.

With over 1,000 systems deployed, Kingstone Robotics integrates ABB, KUKA, and FANUC arms with:

- Force-sensitive sanding and buffing stations

- Closed-loop dimension feedback and tool compensation

- Dust and noise-isolated enclosures

- Rapid product switching via offline programming

Beyond hardware, Kingstone Robotics builds application-specific workflows for high-precision surface finishing—an area where general-purpose platforms often struggle. From pressure calibration to wax dispensing to tool wear compensation, every element of the KS system is engineered to perform in production conditions where safety, repeatability, and aesthetics intersect.

Key Industries Served:

- Automotive – wheel hubs, bumpers, engine cases, gear housings

- Medical – titanium joints, orthopedic implants, prosthetic surfaces

- Aerospace – turbine blades, engine components, high-tolerance parts

- Sanitary hardware – faucets, shower arms, mirror-finished fixtures

Kingstone Robotics doesn’t just sell machines—it delivers fully integrated solutions that streamline production lines, reduce labor reliance, and elevate product consistency in challenging polishing and grinding applications.

Looking to automate your polishing or grinding process? Visit www.kingstonerobotec.com to explore how Kingstone Robotics can help you automate complex finishing operations with confidence.