The Hidden Costs of Robotic Arms and How to Budget Effectively

Purchasing a robotic arm—whether new or used—is only the beginning. For manufacturers planning to automate polishing operations, it is critical to recognize the numerous associated expenses that extend beyond the sticker price of the robot itself. These so-called hidden costs can significantly affect the overall project budget and the return on investment (ROI). Ignoring them can lead to budget overruns, extended downtime, or even underperforming installations.

This article outlines the most common overlooked expenses in deploying a robotic polishing cell. By understanding and preparing for them, companies can more accurately budget and ensure a smoother transition into automation. This is the final article in a four-part series on robotic arms for polishing.

1. Integration and Installation Costs

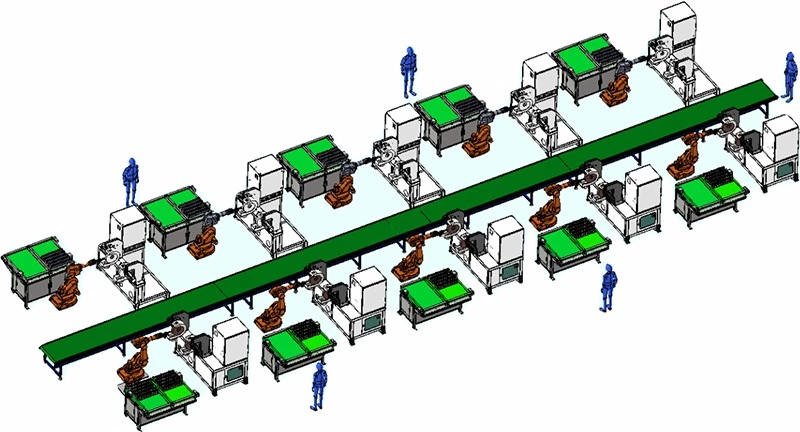

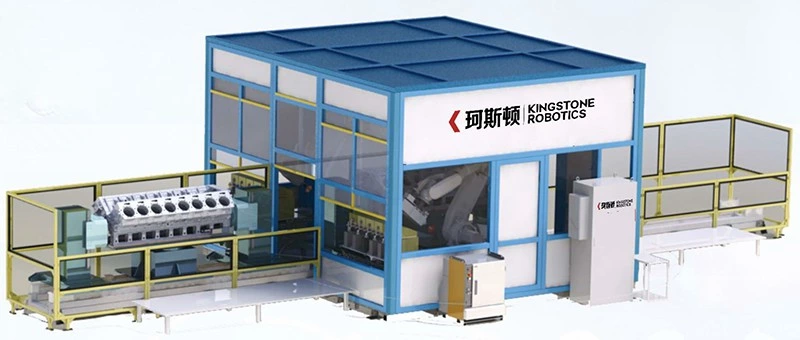

Integration is often the most substantial cost category after the robot purchase. In many cases, the robotic arm represents less than 25% of the total cost of an automation cell. The remaining budget typically goes toward engineering, programming, peripheral devices, safety, and system commissioning.

Key cost components include:

- System Design and Engineering: Designing the layout of the robotic cell, including the robot base, support frame, cable routing, and part-handling systems. For complex polishing systems, this may also involve designing custom part fixtures and simulating robot motion paths using CAD software.

- Programming: Robots need customized motion sequences to polish specific parts. This programming must account for contact force, tool orientation, and multi-surface coverage. Integrators often charge $100–$150 per hour for on-site programming.

- Installation and Setup: Mounting the robot, wiring it to the controller, interfacing it with factory power sources, and testing the setup. This process typically requires rigging, alignment, and validation that the robot coordinates match the physical work environment.

Typical integration costs range from 10% to 30% of the total cell cost. For example, a robot priced at $60,000 may require $18,000 in integration services. For complex multi-station cells, this can exceed $100,000.

| Item | Estimated Cost (USD) |

| Robot (Six-axis) | $60,000 – $80,000 |

| Integration & Programming | $10,000 – $40,000 |

| Custom Fixtures | $2,000 – $10,000 |

| Simulation Software | $3,000 – $15,000 |

| Installation Services | $5,000 – $10,000 |

2. End-of-Arm Tooling (EOAT) and Accessories

A robotic arm cannot polish without a specialized end-effector. End-of-arm tooling (EOAT) for polishing applications often includes:

- Rotary polishing heads

- Compliant sanding tools with pneumatic or spring-loaded mechanisms

- Grinding spindles with speed control and torque monitoring

- Force-torque sensors for adaptive pressure control

These tools must be mounted securely to the robot and often require custom tool flanges or adapters. Moreover, sensors may be necessary to maintain consistent pressure, especially on contoured surfaces.

Tooling can cost from $1,500 for basic setups to over $20,000 for motorized and sensor-integrated systems. Replacement consumables such as belts and polishing pads must also be budgeted as recurring costs.

| Tooling Type | Cost Range (USD) |

| Passive Sanding Tool | $1,000 – $2,000 |

| Active Compliant Tool | $4,000 – $8,000 |

| Force-Torque Sensor | $5,000 – $10,000 |

| Automatic Tool Changer | $3,000 – $7,000 |

| Polishing Media (annual) | $1,000 – $5,000 |

3. Safety Equipment and Compliance

Safety is a legal and operational requirement when deploying robots. Even when collaborative robots are used, compliance with local and international safety standards—such as ISO 10218 and RIA R15.06—is essential.

Necessary components often include:

- Safety fencing or guarding around the robotic cell

- Emergency stop (E-stop) systems and interlocks

- Safety-rated scanners or light curtains if the area is semi-open

- Dust extraction systems for polishing particulate

Safety costs can range from $5,000 for simple fencing to $30,000 for fully integrated scanner systems with automated gate controls.

| Safety Feature | Typical Cost (USD) |

| Fencing (10m² cell) | $3,000 – $7,000 |

| Light Curtains / Scanners | $5,000 – $10,000 |

| E-Stops and Interlocks | $1,000 – $3,000 |

| Dust Collection System | $5,000 – $15,000 |

4. Training and Programming Support

Regardless of the robot brand, a steep learning curve is associated with programming polishing paths. Even if outsourcing programming, in-house staff must be trained to operate, troubleshoot, and maintain the system.

Training costs include:

- OEM programming courses ($1,500–$2,500 per technician)

- On-site training by integrators or third-party experts

- Ongoing support such as hotline or remote diagnostics

Companies should budget at least $5,000–$10,000 for initial training and another $5,000 for post-installation support.

5. Maintenance, Spare Parts, and Ongoing Service

Maintenance is critical to uptime and performance. Robotic arms, particularly in abrasive environments like polishing, require regular inspection and occasional part replacements.

Annual costs typically include:

- Preventive maintenance kits (grease, filters, O-rings)

- Spare cables and sensors

- Software or firmware updates

- Backup EOAT components

Experts suggest setting aside 5–10% of the robot cell’s capital cost annually for maintenance. For a $150,000 system, this would equate to $7,500–$15,000 per year.

6. Facility Modifications and Utility Infrastructure

Before installation, manufacturers must ensure their facility can support the robot and its associated equipment. Key considerations include:

- Electrical Requirements: Many robots need 3-phase 480V or 230V supplies.

- Pneumatics: For compliant tools or tool changers, an air line with sufficient pressure is required.

- Floor Reinforcement: Larger robots may require concrete pads or anti-vibration mounts.

- Dust Management: Local exhaust ventilation (LEV) systems may need to be installed or upgraded.

Depending on site conditions, these modifications can cost from $5,000 to over $25,000.

7. Project Management and Soft Costs

Beyond hardware and installation, projects involve administrative and logistical expenses that should not be ignored:

- Shipping and import duties

- Insurance for equipment

- Project management labor (internal or contracted)

- Licensing and documentation fees

For budgeting purposes, it's advisable to include a 10–15% contingency line to account for these variables. Complex installations may require additional coordination between suppliers, contractors, and regulatory agencies.

Summary Budget Example for a Polishing Cell (Midrange)

| Category | Estimated Cost (USD) |

| Robot + Controller | $70,000 |

| EOAT and Sensors | $18,000 |

| Integration & Programming | $30,000 |

| Safety & Compliance | $12,000 |

| Facility Prep & Utilities | $10,000 |

| Training & Support | $8,000 |

| Project Management / Misc. | $10,000 |

| Total Estimated Cost | $158,000 |

This breakdown illustrates how a robot arm—though highly visible—is only a portion of the actual investment. Planning for the entire scope ensures accurate ROI forecasting.

Best Practices for Budgeting

- Create a comprehensive itemized checklist that includes all cost categories.

- Solicit quotes from multiple integrators, specifying the full scope of services.

- Include at least 10% contingency for unknowns.

- Plan annual maintenance costs into operational budgets.

- Explore tax incentives, such as Section 179 deductions (U.S.) or local automation grants.

- Validate ROI over a realistic time horizon—usually 2 to 3 years for polishing applications.

Conclusion

Hidden costs can derail even well-planned automation projects. For polishing applications, where precision and uptime are non-negotiable, accounting for every category—hardware, integration, tooling, safety, and operations—is essential. By treating the robotic arm as one part of a complete system, businesses can budget effectively and set themselves up for success.

References

- Standard Bots – "How Much Do Robots Cost?" (2025) [https://standardbots.com]

- Motion Controls Robotics – "Should You Purchase a Used Robot?" [https://motioncontrolsrobotics.com]

- Robots Done Right – "Second-Hand vs. New Robots" [https://robotsdoneright.com]

- JH Foster – "Automation Project Considerations" [https://jhfoster.com]

- Keyence, SICK Safety Catalogs – Price and specs for scanners and curtains