5 Common Manufacturing Defects Robotic Deburring Eliminates for Good

In modern manufacturing, perfection isn't just a goal; it's a requirement. Whether you're making a critical aerospace component, an automotive transmission case, or a high-end consumer product, your customers expect flawless quality. Even the smallest imperfection can lead to assembly failures, performance issues, or a poor perception of your brand.

Among the most common and frustrating challenges are the defects left behind by core manufacturing processes: the burrs, sharp edges, and excess material that cling to freshly made parts.

For decades, the default solution has been manual deburring. We all know what this looks like: skilled workers on a production line, using hand tools to grind, file, and polish parts. But this approach is fundamentally flawed. It’s slow, it’s dirty, and its results are only as good as the person doing the work on that particular day. Worker fatigue, skill gaps, and simple human error lead to inconsistent quality. Worse, it’s often a dangerous and physically demanding job, leading to high employee turnover and safety risks.

There is a better way. Robotic deburring technology has matured into a powerful, reliable, and cost-effective solution that permanently solves these age-old problems. At Kingstone Robotics, we specialize in creating turnkey robotic systems that don't just remove defects—they deliver a new level of consistency and efficiency to your entire operation.

Let's explore five of the most common manufacturing defects and see exactly how a well-designed robotic deburring system eliminates them.

1. Burrs and Sharp Edges – The Classic Culprit

What They Are: A burr is a small, sharp ridge of material that remains on a workpiece after machining operations like drilling, milling, or cutting. They are the single most common defect found in metal and plastic manufacturing.

Why They're a Problem:

- Safety: Sharp burrs are a major hazard for both the workers handling the parts and the end-users.

- Assembly: A single, misplaced burr can prevent parts from fitting together correctly, causing jams on automated assembly lines and leading to product failure.

- Performance: In fluid or hydraulic systems, a dislodged burr can contaminate fluids, clog valves, and cause catastrophic system failure.

The Robotic Solution:

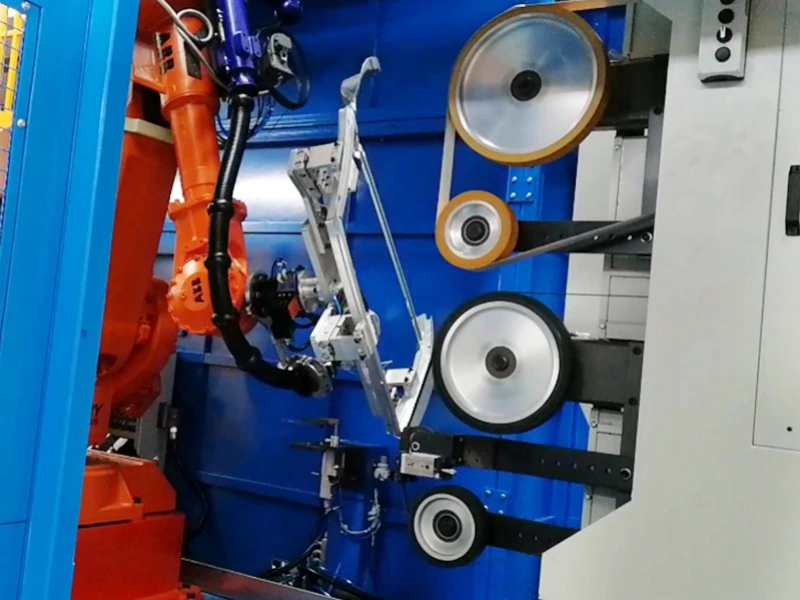

Where a human hand might apply too much pressure here and not enough there, a robot delivers perfection every time. Kingstone Robotics systems use advanced force control technology. This allows the robotic arm to "feel" the surface of the part, applying constant, even pressure with the deburring tool.

Imagine a robot tracing the edge of a complex machined part. It maintains the perfect angle and pressure, removing the burr completely without altering the part's critical dimensions. Its six-axis flexibility allows it to reach into cross-holes, deep grooves, and other tight spaces that are impossible for a person to access consistently. The result isn't just a deburred part; it's a perfectly finished part, every single time.

2. Casting Flash and Parting Lines – The Mark of Imperfection

What They Are: Flash is a thin, unwanted sheet of material that squeezes out of a mold at the parting line—the seam where the two halves of a die-cast or injection mold meet. This seam itself often leaves a visible line on the finished part.

Why They're a Problem:

- Quality Perception: While often cosmetic, visible parting lines and rough flash immediately signal a low-quality product to the consumer.

- Difficult to Remove: Manually removing flash and parting lines from curved or complex surfaces is extremely difficult. It's easy to create flat spots or gouges, ruining the intended geometry and aesthetic of the part.

The Robotic Solution:

This is where the "art" of finishing becomes a science. A Kingstone Robotics system can be programmed to follow the precise 3D path of a parting line, no matter how complex the part's curvature. We often use compliant tooling, such as a floating spindle, which allows the abrasive media to glide gently over the surface.

Think of it like a shock absorber for the grinding tool. It ensures the tool remains in perfect contact with the surface, blending the parting line away seamlessly without digging in or altering the part's shape. For high-volume cast parts, this automated process transforms a quality bottleneck into a smooth, predictable, and efficient step in the production flow.

3. Weld Seams and Spatter – The Finishing Challenge

What They Are: Welding, while essential for fabrication, leaves behind a raised bead (the weld seam) and often scatters small droplets of molten metal (spatter) onto the surrounding surface.

Why They're a Problem:

- Structural Integrity: An uneven weld seam can create stress concentration points, potentially weakening the joint over time.

- Surface Preparation: For a part to be painted or coated properly, the surface must be perfectly smooth. Weld seams and spatter prevent proper adhesion, leading to chipping and corrosion down the line.

The Robotic Solution:

Manually grinding welds is one of the most physically demanding jobs in a factory. It requires immense skill to smooth the weld without removing too much parent material. A robot makes this process precise and effortless.

Our robotic grinding cells often incorporate 3D vision systems. The vision system scans the part to locate the exact position and size of the weld seam. The robot then uses this data to automatically generate a perfect grinding path. It can apply the exact force needed to blend the weld flush with the parent material, creating a smooth, uniform surface that is perfectly prepped for painting. This eliminates the guesswork and physical strain of manual grinding, ensuring every welded joint is finished to the highest standard.

4. Machining Marks and Surface Imperfections – The Quest for a Perfect Finish

What They Are: Even the most advanced CNC machines can leave behind subtle tool marks, chatter, or surface waviness. For parts that require a specific aesthetic or a highly engineered surface, these imperfections are unacceptable.

Why They're a Problem:

- Surface Finish: For parts needing a mirror polish or a specific surface roughness (often measured as an Ra value), any tool marks are disqualifying defects.

- Functional Impact: On parts like turbine blades or pump impellers, a perfectly smooth surface is critical for efficient fluid dynamics. Imperfections create turbulence and reduce performance.

The Robotic Solution:

Achieving a specific surface finish is a multi-stage process. A Kingstone Robotics system can be designed to automate this entire workflow. Using an automatic tool changer, a single robot can perform a sequence of operations:

- Start with a coarse-grit abrasive to quickly remove stock and machine marks.

- Switch to a medium-grit flap wheel to blend and refine the surface.

- Finish with a fine-grit polishing buff to achieve the final, specified Ra value or a mirror shine.

This automated process turns polishing from a slow, inconsistent art form into a fast, repeatable science. We can guarantee the surface finish of every part, delivering a level of quality and consistency that is simply impossible to achieve manually.

5. Gate and Riser Remnants – The Heavy-Duty Hurdle

What They Are: In metal casting, gates are the channels where molten metal enters the mold, and risers are reservoirs that feed the casting as it cools and shrinks. Once the part is solid, these leave large, tough stubs of excess material that must be removed.

Why They're a Problem:

- Extreme Danger: Cutting gates and risers is typically the loudest, dirtiest, and most dangerous job in a foundry. It involves heavy handheld grinders or saws, creating intense vibration, noise, and risk of serious injury.

- Production Bottleneck: This manual rough-finishing stage is often the slowest part of the entire casting process.

The Robotic Solution:

This is a prime example of where automation delivers a massive return on both safety and efficiency. We deploy a heavy-payload robot, armed with a high-torque cutting spindle, inside a fully enclosed and guarded safety cell. The robot has the power and rigidity to cut through tough gate and riser material cleanly and quickly, in a fraction of the time it would take a human.

This doesn't just speed up the line; it completely removes your workers from a hazardous environment. It transforms the most dangerous job in the plant into a safe, quiet, and fully automated process.

Conclusion: Your Partner for a Flawless Finish

Investing in robotic deburring is more than just a capital equipment purchase. It’s a strategic decision to elevate your quality, protect your workers, and build a more efficient and competitive manufacturing operation. It’s about moving from inconsistent, manual processes to a future of predictable, flawless production.

At Kingstone Robotics, we are more than just a robot supplier. We are your automation process partners. We take the time to understand your specific parts, your quality standards, and your production goals. Then, we design, build, and integrate a complete, turnkey solution that is tailored to solve your unique finishing challenges.

Ready to eliminate defects and unlock a new level of quality and efficiency? Contact the expert team at Kingstone Robotics today. Let's start the conversation about designing a robotic finishing solution that's perfect for you.