Comparing New vs. Used Robotic Arms – Costs, Benefits, and Considerations

Investing in a robotic arm for polishing involves more than just choosing the right type of machine. One of the most common dilemmas businesses face is whether to purchase a brand-new robot or go for a used or refurbished unit. The decision can significantly influence your automation budget, long-term maintenance strategy, and operational performance. This article examines the cost difference between new and used robots, explores the practical benefits and limitations of both options, and offers guidance for selecting the right choice based on your polishing application requirements.

Price Difference: New vs. Used Robots

The most striking difference between new and used robotic arms is the upfront cost. Industry sources estimate that used industrial robots cost between 40% to 60% less than comparable new models. This cost advantage can be especially appealing to small businesses or those exploring automation for the first time.

For example, a six-axis polishing robot might retail for $80,000 when new, while a used equivalent in good condition could range between $32,000 to $48,000. The savings at first glance are substantial, but the robot itself often represents only a fraction of the total system cost. Polishing cells require tooling, safety measures, integration, and programming—each contributing significantly to overall expenditure.

A side-by-side breakdown illustrates the broader picture:

| Item | New Robot | Used Robot |

| Robotic Arm | $80,000 | $40,000 |

| Tooling | $5,000 | $5,000 |

| Integration and Programming | $50,000 | $43,000 |

| Additional Restoration | — | $5,000 |

| Total | $135,000 | $93,000 |

These figures show that while the robot price may drop by 50%, the total system savings may hover around 30%. Costs like license transfers, especially for brands like FANUC and ABB, and maintenance parts (batteries, seals, software updates) should not be overlooked, as they may add several thousand dollars.

Advantages of Buying a New Robot

Purchasing a new robot offers unmatched predictability and support, particularly important in environments requiring continuous, high-precision polishing. New units come with warranties that typically span one to two years, covering parts, labor, and technical assistance. This guarantee can be vital when the robot must operate across multiple shifts.

New robots also feature the latest technologies: improved motion control, better energy efficiency, and compatibility with modern software and sensors. For polishing, this translates to better path accuracy, consistent finish quality, and support for force feedback or vision-guided adjustments.

Customization is another key advantage. Buyers can tailor configurations at the time of purchase—selecting specific IO options, IP ratings, and communication protocols. Additionally, new robots are fully supported by OEMs, meaning training materials, spare parts, and integration support are readily available.

Finally, a new unit ensures a known operational history. There's no risk of hidden defects or fatigue from prior use. In a polishing environment, where abrasive dust and high duty cycles can accelerate wear, this factor alone can justify the higher cost.

Advantages of Buying a Used Robot

Used robots provide a more budget-friendly path to automation, particularly beneficial for job shops or smaller manufacturers. Units from reputable resellers are often cleaned, repainted, and equipped with functional controllers and tested joints. Some vendors include limited warranties (3 to 12 months) and basic training resources, easing the transition.

Speed of deployment is another benefit. While new robots might have lead times of 8 to 16 weeks, many used units are in stock and can ship within days. This speed can be crucial for time-sensitive polishing projects.

Used robots also let buyers afford higher-tier models within limited budgets. A company might acquire a refurbished KUKA or ABB robot—originally valued over $100,000—for half the price, thus accessing capabilities otherwise out of reach.

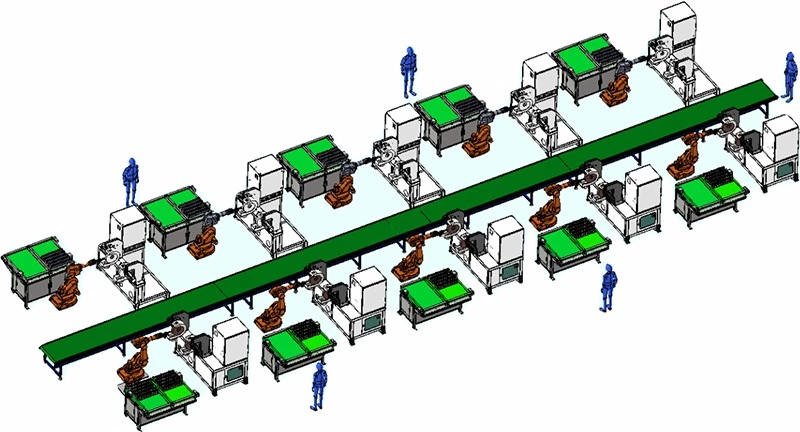

For companies already using specific brands, adding used units of the same type simplifies maintenance, programming, and parts management. This brand standardization enhances operational efficiency across multiple workcells.

Risks and Drawbacks of Used Robots

Used robots naturally come with risks. Most notably, their condition depends heavily on prior usage. Without maintenance logs, it’s difficult to know whether the robot was lightly used in a cleanroom or overworked in a harsh environment.

Wear and tear may affect repeatability. Mechanical components like reducers, bearings, or belts could introduce backlash, making consistent polishing more difficult. Moreover, older robots may lack IP-rated enclosures or integrated force control systems, both important in polishing applications.

Another concern is integration difficulty. Outdated controllers might require legacy software that’s incompatible with current factory systems. Parts availability and technical support may also be limited, especially if the model is no longer supported by the manufacturer.

To mitigate these issues, buyers should:

- Purchase from certified refurbishers.

- Inspect the unit in person or request performance documentation.

- Confirm availability of spare parts and integration support.

- Budget for additional costs like re-greasing, cable replacement, and licensing.

Considerations Specific to Polishing Applications

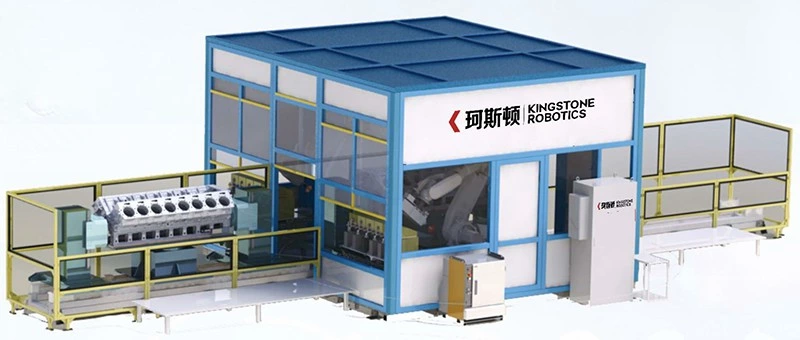

Polishing places unique mechanical and environmental demands on robotic systems. Unlike simple pick-and-place operations, polishing requires adaptive control, consistent contact force, and durability in dusty environments.

For optimal performance, robots used in polishing should meet criteria such as:

- Repeatability of ±0.05 mm or better.

- IP65 or higher ingress protection.

- Integrated or compatible force control systems.

Newer robots offer these features natively, while older models may require external tooling upgrades. For instance, force sensors can be added to older arms, but this increases system complexity and may reduce responsiveness.

In flexible manufacturing or small-batch polishing, modern robots with intuitive programming interfaces (e.g., Universal Robots or ABB GoFa) provide faster changeovers. Used robots can also function in such environments, but setup and programming may demand more expertise.

Environmental sealing is another key factor. Abrasive dust can damage motors and joints. When buying used, it’s essential to ensure the model was originally rated for such conditions or to plan for aftermarket protection.

Making the Decision: New or Used?

Choosing between new and used ultimately depends on operational priorities. The table below summarizes core differences:

| Criteria | New Robot | Used Robot |

| Cost | Higher upfront | 40–60% lower upfront |

| Warranty | 1–2 years typical | 3–12 months if offered |

| Technology | Latest features and software | May lack recent advancements |

| Lead Time | 8–16 weeks | 1–4 weeks |

| Customization | Fully configurable | Limited; fixed specs |

| Environmental Protection | Factory IP65+ options available | May need retrofitting |

| OEM Support | Full manuals and hotline access | Variable; depends on seller |

Manufacturers focused on uptime and process consistency—especially for high-value polishing applications—may prefer new robots. Meanwhile, smaller shops or exploratory automation projects can benefit significantly from used equipment.

One hybrid approach is to use new robots for primary lines and used units in backup or experimental cells. Certified pre-owned programs also exist, blending cost savings with reliability. Leasing options are another route for accessing new robots with minimal upfront capital.

Ultimately, both paths are valid. Success depends on matching technical needs, budget constraints, and risk tolerance with the robot's capabilities and history.

Related Reading

- Guide to Robotic Arms for Polishing: Specs and Costs – Learn about SCARA, six-axis, Cartesian, and cobots, and when to use each based on part geometry and motion needs.

References

- Robots Done Right – https://robotsdoneright.com

- Motion Controls Robotics – https://motioncontrolsrobotics.com

- Standard Bots – https://standardbots.com