2. Boat Slip Buckle Deburring

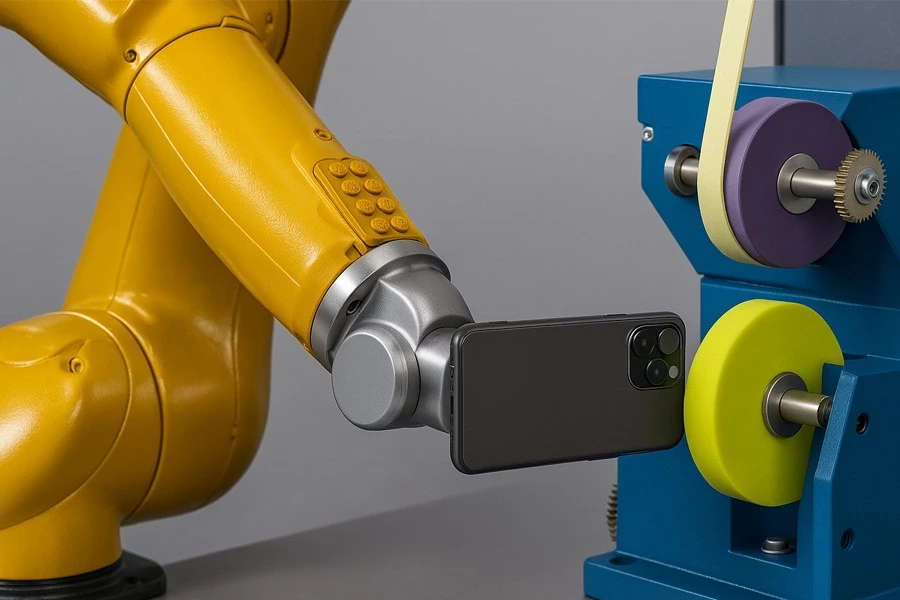

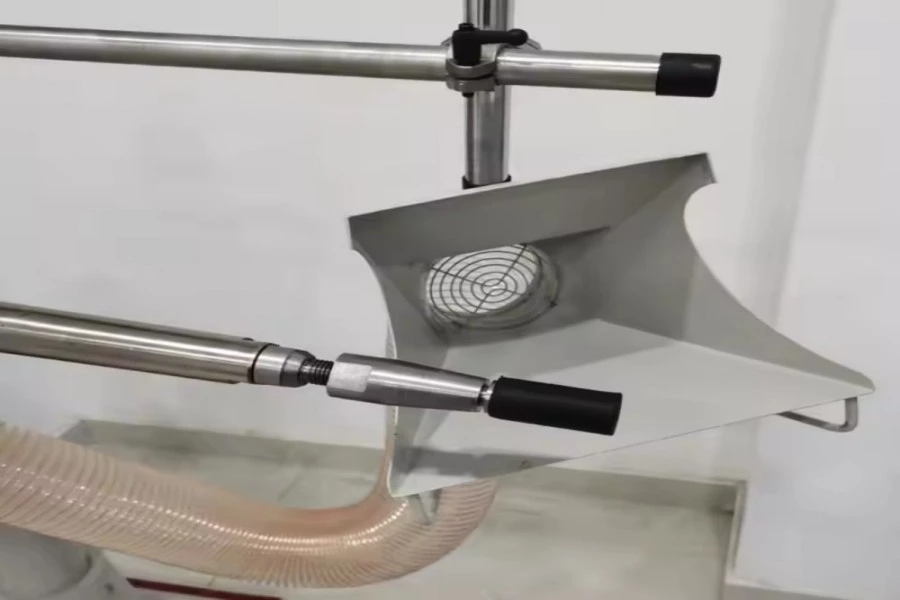

Robotic Configuration: Compact robotic systems with high-speed rotary tools designed for small, intricate components. Force-sensitive end-effectors to adapt to varying material hardness and part geometries. Enclosed work cells with integrated dust extraction systems to maintain a clean working environment. Process Integration: