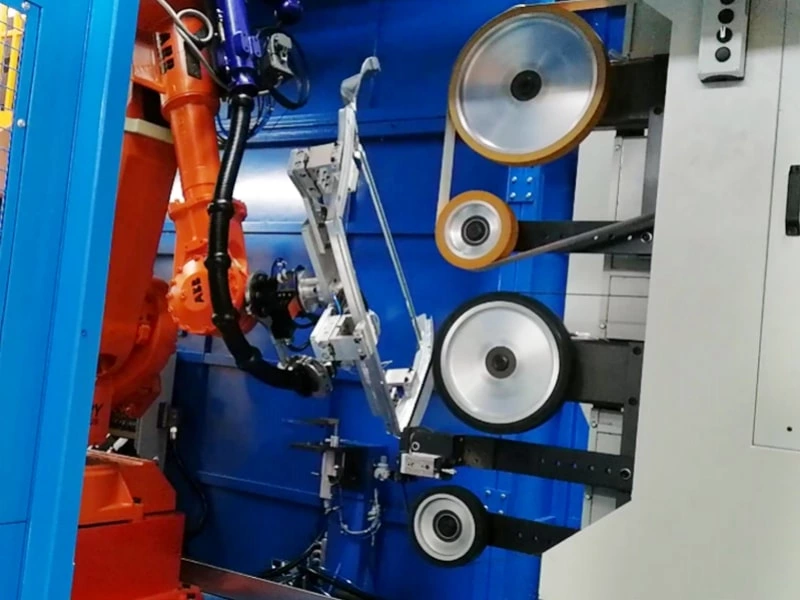

1. Door Pull Handles Grinding

Robotic Configuration: Six-axis robotic arms equipped with adaptive grinding tools to accommodate various handle designs. Integration with vision systems for precise alignment and consistent material removal. Customizable end-effectors to handle different materials, such as stainless steel, brass, or aluminum. Process Integration: Automated grinding of door pull handles to remove casti ...