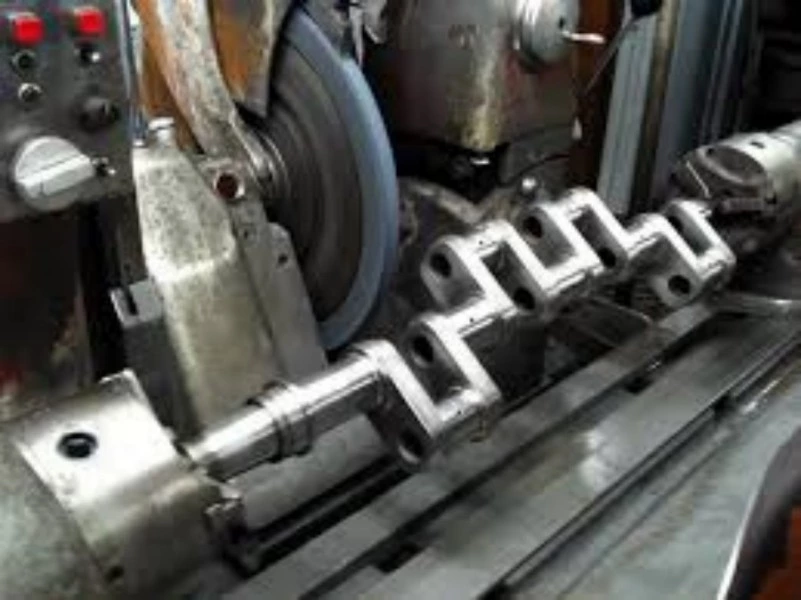

4. Crank Grinding

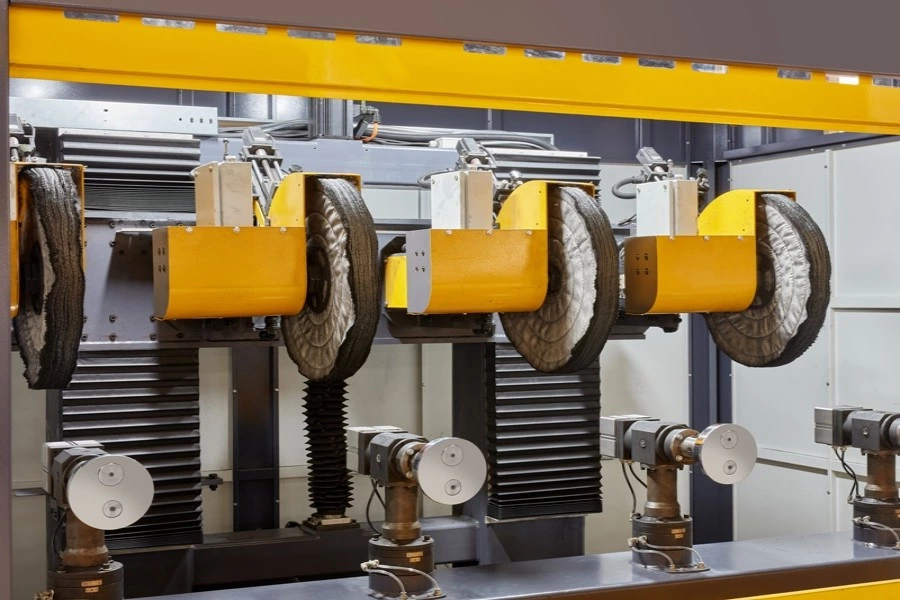

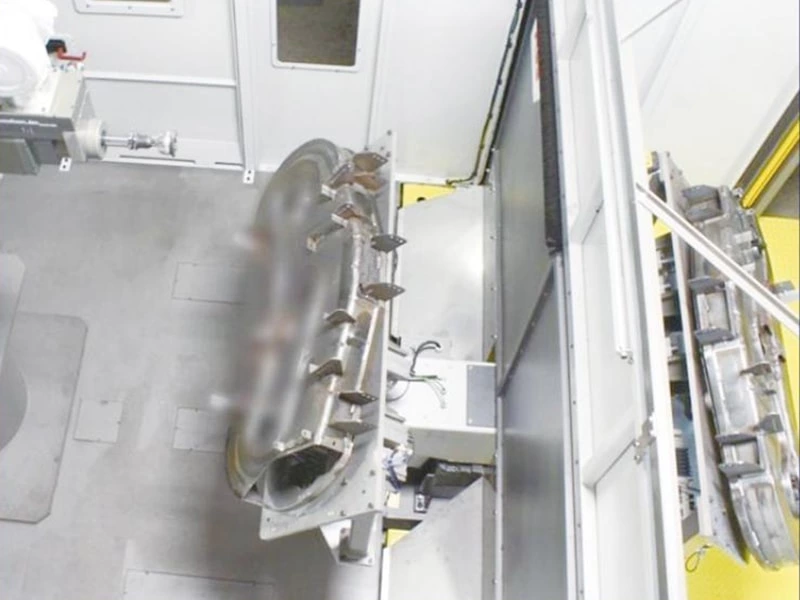

Robotic Configuration: Heavy-duty robotic systems with high-torque grinding spindles designed for crankshaft applications. Precision positioning systems to ensure accurate material removal and surface finish. Integrated cooling systems to manage heat generated during grinding operations. Process Integration: