How Fast Can You Deploy a Robotic Grinding System?

In today's competitive manufacturing environment, speed to deployment is a critical factor for staying competitive. Whether your team is producing automotive components, die-cast parts, or sanitary hardware, the time it takes to get a robotic grinding system up and running directly impacts your return on investment (ROI), workforce planning, and product quality consistency. Accelerated deployment not only ensures ROI but also helps manufacturers stay ahead in product delivery, compliance, and workforce management.

But how quickly can you realistically deploy a robotic grinding system?

This article explores the main factors that influence deployment time, the realistic timelines for different project types, and how system integrators like Kingstone Roboticscan help manufacturers speed up deployment while ensuring high-quality results.

Why Deployment Speed Matters

For mid- to high-volume manufacturers, every week of delay in grinding automation often results in:

- Additional labor costs for manual finishing

- Delayed fulfillment or penalties on OEM contracts

- Inconsistent surface quality across batches

- Prolonged exposure of workers to hazardous dust and noise

Given that robotic grinding can improve consistency by up to 30% and reduce injury risk by over 40%, time-to-deployment becomes a critical metric—not just a planning detail.

What Influences Robotic Grinding Deployment Timelines?

Robotic grinding automation presents unique challenges that set it apart from other robotic applications:

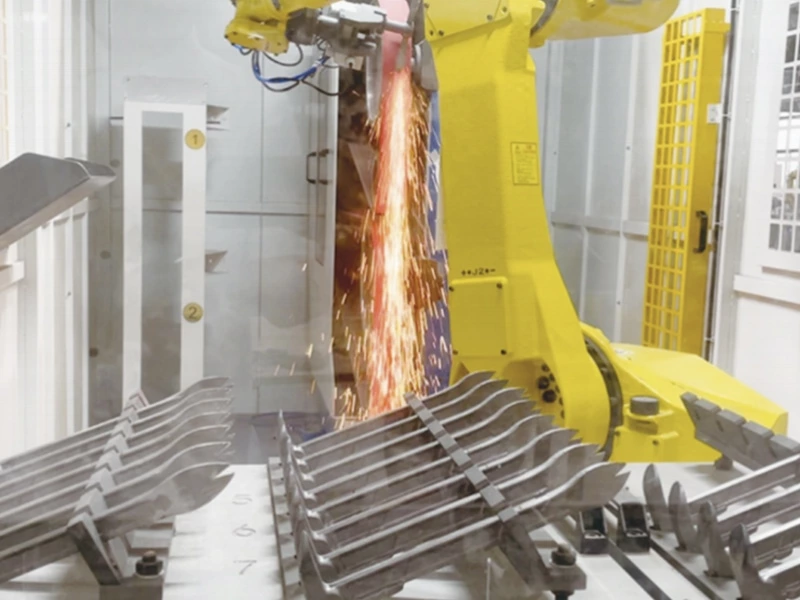

1. Part Complexity and Material Diversity

Grinding aluminum castings differs drastically from stainless steel sanitary ware. Multi-contour parts like turbine blades require advanced force feedback control and path customization.

Impact: Complex geometries need longer simulation and validation.

2. Process Scope: Single Station vs. Full Line

- A standalone polishing cell may take 2–4 weeks.

- A multi-station line may extend to 2–3 months.

Kingstone Robotics Note: Our modular cells shorten configuration time by 30–40% for standard applications.

3. Integration Environment

Inline CNC integrations, safety zoning, dust control, and fixture interfaces affect deployment speed.

Reality Check: Pre-installed infrastructure can save 1–2 weeks.

For instance, if the facility already has a dedicated dust extraction system and power routing for robotic arms, installation time can be reduced by several days. Conversely, if the customer’s site lacks compatible PLCs or standardized signal communication (e.g., between the CNC and robot controller), it can delay both mechanical setup and IO testing. Integration complexity increases further when existing conveyors or jigs are not dimensionally compatible with robotic cells, requiring either customization or interface conversion modules. Kingstone Robotics often conducts a pre-deployment audit to identify these potential mismatches early and recommend adjustments upfront.

4. Programming and Tooling

Offline programming and force-controlled tools reduce debugging time significantly. This approach reduces iterative tuning by dynamically adjusting for abrasive wear and part geometry deviation, especially useful in multi-contour components like pump housings or turbine blades.

Kingstone Robotics Optimization: Auto-compensation modules cut cycle tuning time by up to 50%.

Realistic Timeline: From PO to Production

| Stage | Estimated Duration | Remarks |

| Requirement clarification & sample analysis | 1 week | Includes force mapping, material response testing |

| System proposal & approval | 1–2 weeks | Depending on internal approval speed |

| Mechanical & electrical design | 2–3 weeks | CAD layout, safety cage design, controller integration |

| Assembly & in-house debugging | 2–3 weeks | Tool path validation, wax spray, abrasive wear testing |

| On-site installation | 1 week | Transport, mechanical fitting, cable routing |

| Final tuning & training | 1 week | Product changeover simulation, operator training |

| Total Deployment Time | ~8–11 weeks | Under standard workload and single-cell scope |

Standard units from Kingstone Robotics can reduce this to 4–6 weeks.

How to Speed Up Robotic Grinding Deployment

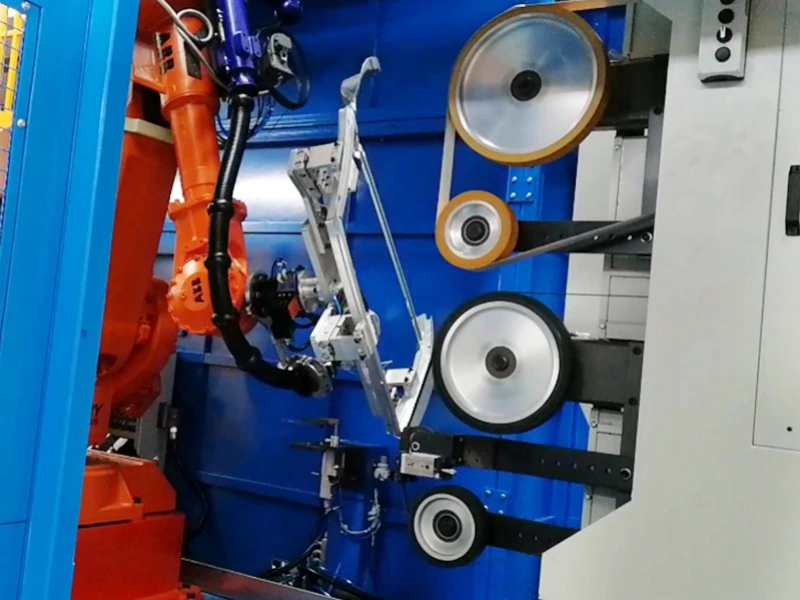

- Standardized Modules

Pre-assembled robotic units with polishing wheels, floating tools, and double-station sanding reduce setup complexity.

- Offline Programming & Process Library

Simulation-ready programs and consumable databases enable fast job switching.

- Remote Support

Smart diagnostics tools allow remote commissioning, reducing on-site setup by 25–35%.

- Robot Brand Familiarity

Partnering with ABB, KUKA, FANUC ensures seamless integration and faster path validation.

Common Pitfalls That Delay Projects

To stay realistic, here are some common causes of delays:

- Incomplete CAD or sample data: Delays in defining part surfaces can push simulation timelines.If the submitted CAD files lack accurate surface normals or fillet transitions, offline path planning becomes unreliable, especially for edge blending or complex transitions. In cases where parts have compound curves or undercuts, Kingstone's simulation software requires high-fidelity 3D geometry to generate correct force vectors and collision-free tool paths. Missing details like bolt holes, parting lines, or material boundaries often force engineers to redo scanning or request new models—resulting in avoidable weeks of rework. That’s why Kingstone recommends clients provide STL/STEP files along with physical samples for initial feasibility validation.

- Facility readiness issues: Missing dust control infrastructure or power supply adaptations.

- Over-customization requests: When clients insist on non-standard software logic or brand-specific sensors, debugging cycles may triple.

- Inexperienced integrators: A general-purpose automation integrator may take 30–50% longer than a grinding-specialized provider like KS Robotech.

Beyond Speed: What Not to Sacrifice

While deployment speed is important, it should never come at the cost of:

- Operator safety: Grinding cells must include proper enclosure, dust filtration, and E-stop logic.

- Product quality consistency: No amount of speed matters if burrs are left behind or polish variation exceeds ±0.1mm.

- Ease of changeover: Systems must be built with flexibility for future parts.

Kingstone Robotics uses closed-loop control and parametric design to deliver repeatable, scalable results.

Conclusion: Fast, But Smart

A robotic grinding system can go live in 4–6 weeks when planned right. The key is combining modular design, experienced integration, and smart feedback systems.

Looking to estimate your robotic grinding system deployment timeline? Learn how fast you can implement automation with Kingstone Robotics at www.kingstonerobotec.com.