Beyond the Manual: A Practical Guide to Automating Your Sanding and Finishing Processes

For any business involved in manufacturing, the finishing stage is critical. It’s where craftsmanship meets quality control. Yet, manual sanding and finishing remain one of the most challenging processes to get right. It’s physically demanding, skill-dependent, and a common source of workplace injuries and production bottlenecks.

The tell-tale signs are familiar: inconsistent finishes from one worker to another, high staff turnover for sanding jobs, and a constant struggle to meet production quotas without compromising on quality. If this sounds like your workshop or factory floor, you've likely considered the solution: automation.

But "automation" isn't a single magic bullet. It's a spectrum of solutions, each with its own ideal applications, benefits, and costs. This guide will walk you through the three primary paths to automating your sanding tasks, helping you understand which approach is the perfect fit for your materials, production volume, and business goals.

Path 1: Dedicated Automatic Sanding Machines

The most traditional approach to automation is the dedicated automatic sanding machine. Think of these as highly specialized, stationary workhorses.

These machines are engineered to perform a single, repetitive task with extreme efficiency. Common examples include wide-belt sanders for large flat panels, edge sanders for finishing the sides of components, and profile sanders for mouldings and more complex shapes. A workpiece is fed into the machine, it performs its specific sanding operation, and the finished piece comes out the other side.

When is this the right choice?

- High Volume, Low Mix: Your production is focused on thousands of identical or very similar parts.

- Simple, Consistent Geometry: You primarily work with flat panels, straight edges, or consistent profiles.

- Speed is the Priority: The goal is to process as many parts per hour as possible.

- The Trade-Offs:

While incredibly fast for the right job, these machines are inflexible. A wide-belt sander can't finish a curved chair leg, and an edge sander is useless for a flat tabletop. If your product line changes or you introduce new designs, the machine may become obsolete. They also require a significant physical footprint and capital investment.

Path 2: Industrial Robotic Sanding

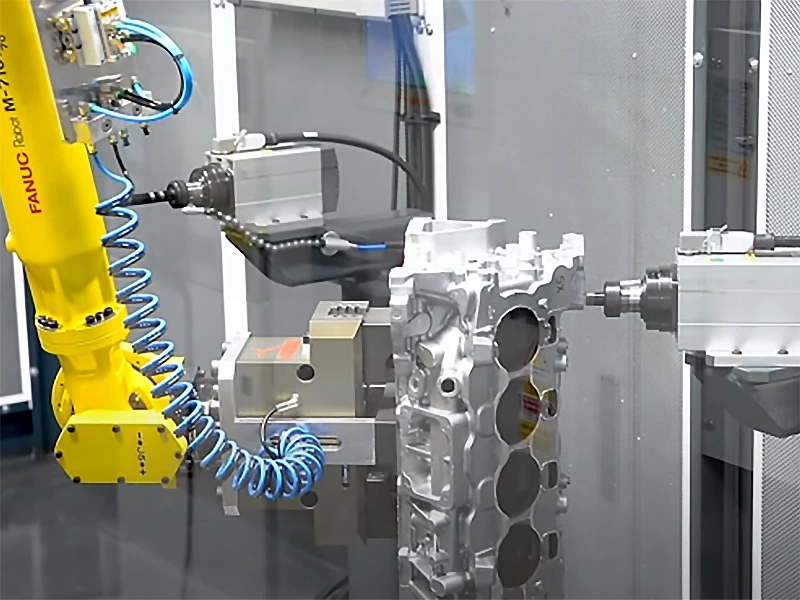

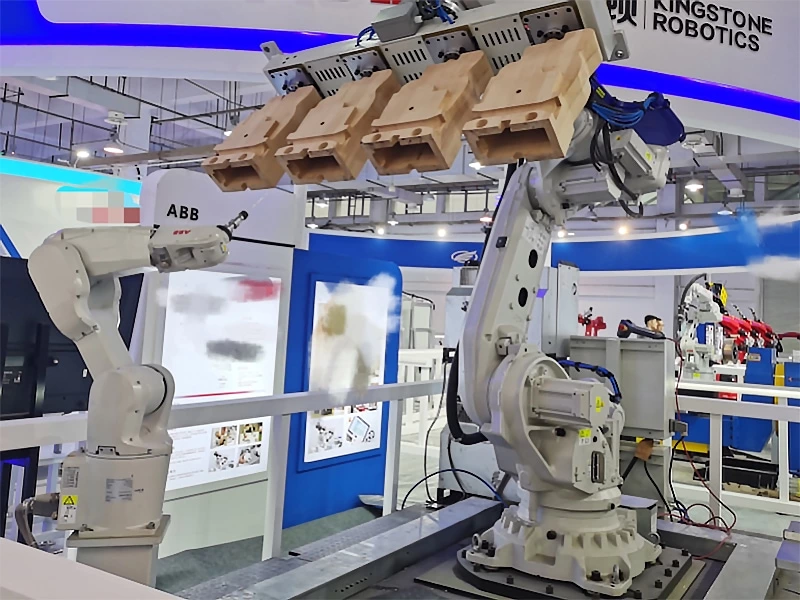

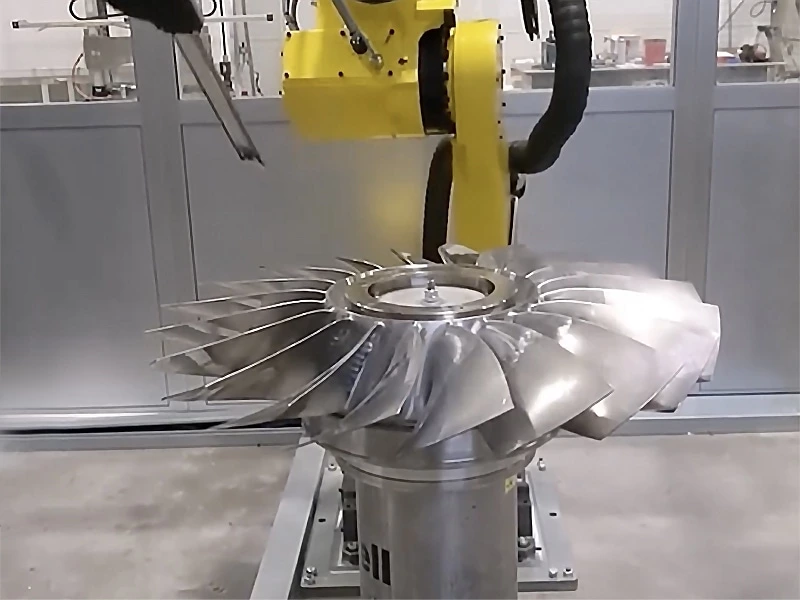

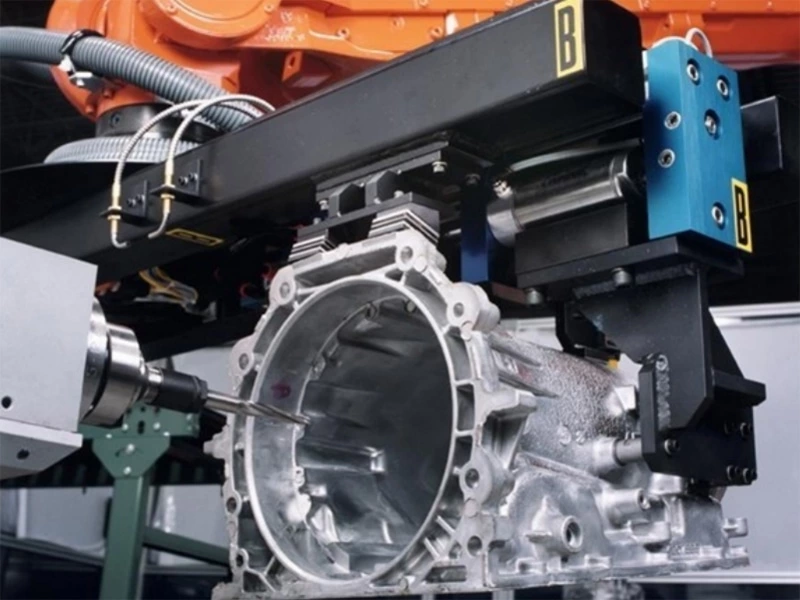

This is what most people picture when they think of modern manufacturing. An industrial robot—a powerful, multi-axis arm—is enclosed in a safety cell and equipped with a professional-grade sanding tool. It’s a solution built for power, precision, and endurance.

Guided by a detailed program, the robotic arm can manipulate the sanding tool across complex surfaces with a level of consistency that is impossible to achieve manually, shift after shift.

Key Components of a Successful Robotic Sanding Cell:

- The Robot Arm: Chosen for its reach, payload capacity (to handle the tool and pressure), and number of axes, which determines its range of motion.

- End-of-Arm Tooling (EOAT): This is the business end. It could be a random orbital sander, a belt sander, or a custom tool. The EOAT often includes its own compliance or "float" to absorb minor variations in the part surface.

- Force-Torque Sensors: This is the technology that elevates robotic sanding from good to great. A sensor at the robot's wrist provides real-time feedback, allowing the arm to maintain a perfectly consistent pressure against the surface, regardless of curves or contours. This prevents gouging and ensures a flawless, uniform finish.

- Programming & Safety: The system is programmed to follow a precise path. Due to the robot's power and speed, the entire cell must be enclosed by safety fencing, light curtains, or area scanners to protect workers.

When is this the right choice?

- Complex Geometries: You manufacture parts with intricate curves and surfaces, like automotive bodies, aerospace components, or high-end furniture.

- High-Stakes Quality: The surface finish requirements are exceptionally high and non-negotiable.

- Demanding Materials: The process involves sanding hard metals or composites that would quickly fatigue a human worker.

The Trade-Offs:

Industrial robots represent a significant investment in both capital and integration expertise. The required safety caging consumes valuable floor space, and programming complex paths for new parts can require a skilled robotics technician.

Path 3: Collaborative Robot (Cobot) Sanding

The newest and most flexible path is sanding with a collaborative robot, or "cobot." Cobots are designed to work safely alongside human employees without the need for extensive, bulky safety fencing (following a risk assessment). They are lighter, easier to program, and more adaptable than their industrial counterparts.

A typical cobot sanding setup involves mounting a lightweight cobot arm to a table or mobile cart. A worker can position a part, and the cobot performs the repetitive, strenuous sanding task. This frees up the skilled employee to handle more value-added work, like quality inspection, assembly, or preparing the next part.

When is this the right choice?

- High-Mix, Low-Volume Production: You handle a wide variety of parts in smaller batches. The ease of "teaching" a cobot a new path by simply guiding its arm makes changeovers fast and simple.

- Human-Robot Teamwork: The process benefits from a human's cognitive skills and a robot's consistency. For example, a human can position a large, awkward piece while the cobot performs the delicate finishing work.

- Limited Floor Space: You don't have room to install a large, fenced-off industrial cell.

- Phased Automation: It’s an excellent first step into automation due to a lower initial investment and faster deployment time.

The Trade-Offs:

Cobots are generally slower and less powerful than industrial robots. They are not the ideal solution for heavy-duty material removal or high-speed, mass-production applications. Their strength lies in their flexibility and collaborative nature, not raw power.

Making the Right Decision: Key Factors to Consider

Choosing the right path requires looking beyond the technology and analyzing your specific operational needs.

- Analyze Your Parts: What are the size, shape, complexity, and material of the parts you are sanding?

- Evaluate Your Volume: Are you making ten unique pieces a day or ten thousand identical ones?

- Define Your Quality Standard: What level of surface finish is required? Is it for a rough pre-paint prep or a Class-A automotive finish?

- Assess Your Team's Skills: Do you have in-house robotics programmers, or do you need a solution that is easy for your existing team to learn and operate?

- Calculate the True ROI: Factor in not just the initial cost, but also labor savings, reduced material waste from rejects, improved safety (and lower insurance premiums), and increased production throughput.

Conclusion: Your Partner in a Perfect Finish

Automating your sanding process is one of the most effective ways to improve quality, increase productivity, and create a safer workplace. The choice between a dedicated machine, an industrial robot, or a collaborative robot depends entirely on your unique application.

The key is to move from asking "Can I automate this?" to "How should I automate this?" By understanding these three distinct paths, you are now equipped to have a more productive conversation and find the solution that will deliver the best return on investment for your busines