Solution Of Automotive Parts Automatic Polishing And Grinding

As the automotive industry accelerates its transformation toward high-end, lightweight, and intelligent development, the market demands higher precision, consistency, and production efficiency in automotive components. Every part must maintain consistent quality and flawless surface finish.

Traditional manual polishing methods, however, face challenges like unstable precision, low efficiency, harsh working conditions, and rising labor costs, making them inadequate for modern automotive manufacturing needs.

Addressing these pain points, this solution introduces an automated polishing, grinding, and deburring system for automotive components that combines precision alignment, intelligent efficiency, and green safety. By integrating cutting-edge technologies such as robotics, visual inspection, and adaptive grinding, it provides end-to-end automated polishing for engine blocks, transmission housings, wheel hubs, and body structures, enabling intelligent upgrades and enhancing core competitiveness.

I. Core Objectives of the Plan

- Precision Quality Assurance: The closed-loop control system ensures component surface roughness meets customer specifications, with flatness, roundness, and other dimensional tolerances controlled within ±0.01mm. The polishing consistency reaches approximately 98%, eliminating defects caused by manual operations such as scratches, over-polishing, or under-polishing.

- Efficiency maximization: A single device achieves 3-5 times higher processing efficiency than manual operation, enabling uninterrupted and stable 24/7 operation. This significantly reduces production cycles and meets the large-scale batch production demands of the automotive industry.

- Cost optimization: Reduce labor costs by over 80% for frontline operators, minimize abrasive material waste, precisely control material usage, lower equipment maintenance expenses, and enhance overall production efficiency.

- Safety and Greenification: The work environment is enclosed with dust collection and exhaust gas treatment systems, achieving a dust purification efficiency of 99.5% or higher. The enclosed workstation reduces noise levels, eliminating hazards from dust and noise to operators, in compliance with national environmental protection and safety production standards.

II. Core Application Scenarios and Compatible Component Types

Kingstone Robotics can provide professional solutions and customized adaptations based on the material (aluminum alloy, copper alloy, cast iron, stainless steel, electroplated parts, plastic parts, etc.), structure (flat, curved, special-shaped structures), dimensions, and process requirements of different components. Its core application scenarios and corresponding components are as follows:

| Application Scenarios | Adapter Parts | Core Process Requirements |

| Engine/transmission core components | Engine block, cylinder head, crankshaft, camshaft; transmission housing, gears | High-precision deburring and surface polishing with high gloss, avoiding damage to critical areas such as sealing surfaces and oil passage holes. |

| Body structural member | Car door frame, engine hood, trunk lid, frame longitudinal beam/beam | Weld grinding, chamfering, and surface leveling to ensure subsequent paint adhesion |

| Wheel hub and brake system components | aluminum alloy wheel hub, brake disc, brake caliper | Surface high-gloss polishing, oxide layer removal, chamfering, and deburring to enhance visual texture and assembly precision |

| New energy vehicle exclusive parts | Battery housing, motor housing, and electrical control box | Precision grinding of lightweight materials (aluminum alloy/carbon fiber) to prevent material damage and ensure sealing performance |

III. Overall Scheme Architecture

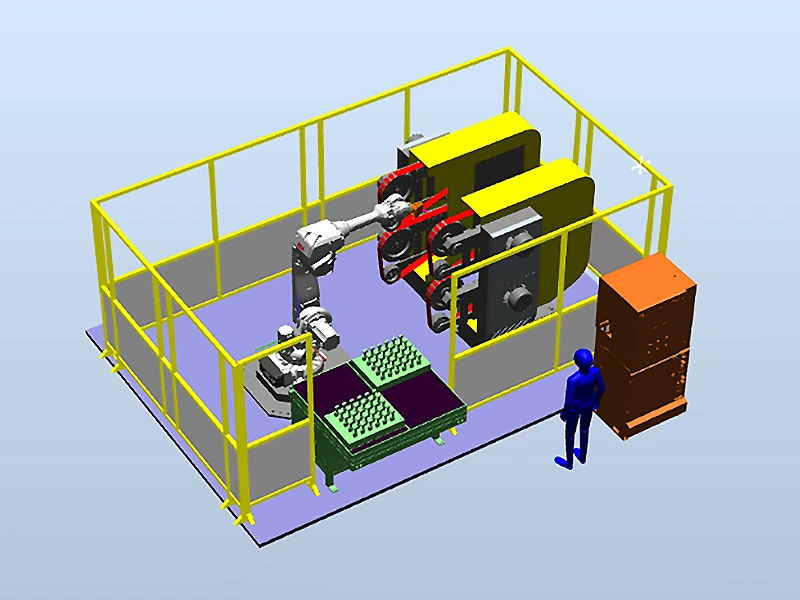

This solution adopts a "modular design and integrated architecture" framework, comprising five core systems: Feeding & Positioning System, Robotic Grinding Execution System, Visual Inspection & Closed-Loop Control System, Dust Purification & Safety Protection System, and Intelligent Operation & Data Management System.

These systems work in synergy to achieve end-to-end automated closed-loop operation, covering the entire process from component feeding, precise positioning, grinding execution, quality inspection, and finished product discharge.

(1) Feeding and Positioning System: Precise Benchmarking, Stable Feeding

As the foundation of automated grinding, this system ensures precise positioning and stable posture of components during the process, thereby guaranteeing subsequent grinding accuracy.

- Feeding System: The unit adapts to component types with tailored feeding methods, including conveyor belt feeding (for small-to-medium components), truss manipulator feeding (for large/heavy-duty components), and AGV unmanned vehicle feeding (for flexible production lines). Equipped with material detection sensors, it precisely synchronizes feeding and grinding rhythms to resolve inconsistent material quality and ensure high yield rates.

- Precision Positioning Unit: The system employs a dual positioning approach combining mechanical alignment and visual correction. Mechanical alignment uses customized fixtures to initially secure components, with fixture materials selected based on part characteristics (e.g., soft materials to prevent damage to aluminum alloy surfaces). Visual alignment captures component contours through 3D cameras, detects deviations between actual and theoretical positions, and feeds this data back to the control system to drive the robot's attitude correction. The positioning accuracy reaches ±0.005mm, ensuring flawless grinding positions.

- Material feeding and sorting unit: After grinding, the robotic arm feeds components onto the conveyor belt. The closed-loop control system and technical inspection automatically sort products into finished items and rework items. Rework items are sent to the reflow channel for re-grinding, while finished items proceed to the next production stage, ensuring strict quality control of high-precision products.

(2) Robot Grinding Execution System: Core Power, Adaptive Grinding

- Core Robot Selection: Choose robots based on component dimensions, weight, and grinding complexity. Small-to-medium components (e.g., hubs, gears) require 20-60kg robotic arms with four-station belt grinders and jute wheel polishing machines. Heavy-duty components (e.g., engine blocks, frames) need 10kg robots with deburring tool tables and dust-proof integrated workstations. For irregular curved surfaces (e.g., body panels), collaborative robots with flexible posture adjustment are recommended. Ensure repeatability accuracy of ≤±0.01mm to maintain consistent grinding trajectories.

- Adaptive Grinding Tool Unit: Featuring a multi-tool library (single/dual/quad-station flexible belt grinder/bristle wheel grinder), it automatically switches between grinding wheels, sandpaper, polishing wheels, and bobbins to suit various processes, including rough grinding, fine grinding, and polishing. The core grinding spindle with constant force control detects surface irregularities in real-time through force sensors, dynamically adjusting pressure and feed rate to prevent over-grinding or under-grinding. The adjustable-speed spindle enables precise speed customization—high-speed, high-pressure for rough grinding, and low-speed, low-pressure for fine grinding.

- Grinding Trajectory Planning: Based on the 3D model of components, the system pre-plans grinding trajectories through offline programming software, supporting various trajectory types, including points, lines, surfaces, and curved surfaces. It also features real-time trajectory correction with visual inspection to provide feedback on component surface conditions, dynamically adjusting the grinding trajectory to ensure comprehensive grinding of complex structures (e.g., oil passage holes, welds).

Related Reading: Precision Grinding: Understanding the Principle, Types, and Applications

(3) Visual Inspection and Closed-loop Control System: Real-time Monitoring and Quality Assurance

- Process Monitoring Unit: The unit captures the grinding process in real-time via visual cameras to monitor tool wear and grinding trajectory deviation. It is also equipped with force, torque, and temperature sensors to collect real-time data on grinding pressure, spindle torque, and tool temperature, thereby preventing grinding defects caused by equipment abnormalities.

- Finished Product Inspection Unit: Utilizes visual inspection technology to conduct comprehensive quality testing on ground components. Inspection items include surface roughness, form and position tolerances, and surface defects (scratches, dents, residual burrs). Inspection data is automatically stored and generates quality inspection reports.

- Closed-loop Control System: The system compares finished product inspection data against preset standards. If deviations are detected, it automatically analyzes the causes (e.g., insufficient grinding pressure, trajectory deviation, etc.) and feeds correction commands back to the robotic grinding system to adjust parameters (pressure, speed, trajectory). Simultaneously, the data is synchronized to the data management system, forming a closed-loop control cycle of "grinding-inspection-correction-optimization" to continuously improve grinding precision and consistency.

(4) Dust Purification and Safety Protection System: Environmentally Friendly and Safe Operation

- Sealed working environment: The grinding area is equipped with a fully enclosed protective cover made of explosion-proof and impact-resistant materials to prevent dust leakage and flying grinding debris. The protective cover is fitted with an observation window for operators to monitor the working status in real time.

- High-Efficiency Dust Purification Unit: Featuring a dual-stage purification process combining cyclone separation and pulse-jet bag filtration, this system effectively removes airborne dust particles to achieve superior air purification. The integrated workstation combines robotic polishing execution systems with the high-efficiency dust purification unit, operating on a closed-loop mechanism of "source capture + intermediate filtration + end-of-line discharge". Designed for precision polishing in automotive, aerospace, and 3C industries, it delivers over 99% dust removal efficiency, precise filtration accuracy, and low emission concentrations while enhancing polishing efficiency and yield rates.

- Safety Protection Unit: Equipped with safety devices such as emergency stop buttons, safety grilles, and gas detection sensors, the dust concentration sensor continuously monitors dust levels in the workshop and pipelines. When exceeding the standard, it automatically triggers an alarm and activates emergency measures, immediately stopping equipment operation. Additionally, noise reduction devices are installed to keep operational noise below safety standards, ensuring the physical and mental well-being of operators.

(5) Intelligent Operation and Data Management System: Digital Control for Efficient Operations

- Equipment Maintenance Management: Real-time monitoring of operational parameters (speed, load, temperature, vibration) for robots, grinding spindles, sensors, and other equipment. Through big data analysis, it predicts equipment failure risks and issues, and maintenance alerts in advance (e.g., bearing replacement, lubricant replenishment, excessive dust levels). A maintenance log is established to record details such as maintenance time, content, and replaced components, enabling full lifecycle management of equipment and reducing failure rates.

- Production Data Management: Automatically collects production output, grinding time, equipment utilization, material consumption, and other data to generate production reports (daily, weekly, monthly), providing an intuitive view of production efficiency. Supports comparative analysis between production plans and actual production data, helping enterprises optimize production plans and improve capacity utilization.

- Quality data traceability: By correlating and storing parameters such as grinding specifications, inspection results, operator details, and equipment serial numbers for each component, a unique product traceability code is generated. This enables end-to-end quality tracking, allowing rapid identification of root causes for quality issues and minimizing losses.

- Remote monitoring and control: Supports remote viewing of production line status, production data, and quality reports via devices such as computers and smartphones. When equipment malfunctions occur, remote alarm alerts are issued. Additionally, remote debugging of equipment parameters is supported to enhance operational efficiency and reduce maintenance costs.

IV. Key Technological Advantages From Kingstone Robotics

- Closed-loop programming: The product requires high quality and dimensional accuracy. The program implements an automated closed-loop system of "sensor monitoring → data judgment → actuator action → re-monitoring" to replace manual intervention, ensuring the system remains in a stable, safe, and compliant operating state.

- The closed-loop feedback mechanism operates through a self-regulating cycle: sensors collect data → controllers analyze deviations → actuators adjust actions → sensors collect feedback again. This system automatically maintains safe and efficient operation without human intervention. In essence, it enables the system to "monitor, judge, and correct itself," forming a self-regulating closed-loop system.

- Standard Consumables Process Library: A standardized data management system for production manufacturing, featuring a structured framework that encapsulates general consumables (e.g., filter materials, cutting tools, cutting fluids), including selection criteria, technical parameters, replacement cycles, and safety protocols. This enables "consumables selection per process, quality control via data, and cost reduction through standardization," tailored for industrial applications such as dust purification and mechanical processing. Customized robotic grinding consumables are developed for clients' specific product processes.

- Modular and flexible design: Each system adopts a modular design, allowing flexible combinations based on customer production requirements; supports rapid switching of multiple types of components (type change time ≤30 minutes), aligning with the automotive industry's trend of multi-model and small-batch production.

- Open-parameter design: By categorizing parameters into four tiers—core safety, process standards, operational adaptability, and expansion reserves—this framework ensures system standardization and safety while providing field personnel with flexible customization options. Integrated with a standardized consumables process library and closed-loop control system, the design enables rapid adaptation to diverse operational conditions and material types, achieving end-to-end flexible management of "process-consumables-control". Particularly suited for multi-variety, small-batch, flexible production scenarios.

V. Applicable Customers and Application Value

This solution is designed for automotive manufacturers, auto parts suppliers, new energy vehicle (NEV) companies, and other automotive-related businesses, particularly for clients with the following needs:

- The artificial polishing and grinding precision is unstable, the product quality fluctuates greatly, and it is difficult to meet the high-end market demand.

- Rising labor costs and low production efficiency make it difficult to meet the demands of mass production.

- The polishing and grinding operations are conducted in harsh environments with severe dust and noise pollution, posing significant challenges to both environmental protection and workplace safety.

- The demand for multi-variety and small-batch production is prominent, and the cost of changing the traditional production line is high, as well as the efficiency.

This solution enables customers to automate and smartly upgrade polishing processes, significantly improving product quality and production efficiency while reducing costs and safety/environmental risks. It also strengthens core competitiveness, helping enterprises gain a competitive edge in the automotive industry's transformation and development.