Selection Guide Of Polishing Robot In Different Industries

In the wave of manufacturing automation upgrades, polishing robots have become core equipment in surface treatment processes across industries, thanks to their stable operational precision, efficient polishing capabilities, and excellent adaptability to working environments.

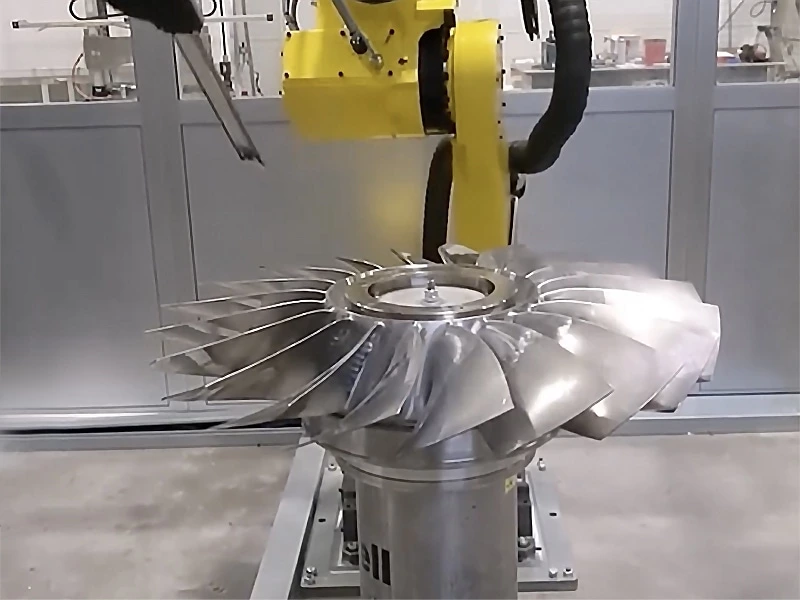

Stainless Steel Casting Polishing and Grinding Workstation

As a critical process ensuring product appearance quality and performance, polishing directly impacts market competitiveness.

- For 3C electronics, precision polishing determines product aesthetics and tactile comfort.

- For automotive components, high-quality polishing ensures safety and durability.

- While for aerospace core parts, polishing accuracy directly affects equipment stability and service life.

However, varying material types, structural forms, precision requirements, production scales, and working environments across industries create distinct demands for polishing robots' performance parameters, functional configurations, and process compatibility.

Improper selection not only fails to leverage automated polishing advantages but may also lead to reduced product pass rates, decreased production efficiency, and skyrocketing equipment maintenance costs.

Therefore, precisely matching polishing robot selection to industry-specific requirements is the key prerequisite for enterprises to achieve automated transformation in polishing processes successfully. This article analyzes different industries to highlight these challenges.

I. Core General Dimensions for Polishing Robot Selection

Regardless of the industry, selecting polishing robots must prioritize core technical parameters and basic configurations as the foundation. This ensures precise alignment between equipment and operational requirements.

The interdependence and mutual influence of these parameters collectively determine the robot's operational capabilities and applicability.

Below, we will analyze five key universal dimensions critical during selection, clarifying the selection logic and compatibility standards for each parameter.

1. Repeatability

- As a core performance parameter of polishing robots, repeatability directly determines the uniformity, consistency, and precision level of polished surfaces.

- It refers to the range of deviation of the robot's end effector when repeatedly reaching the same target position. Smaller deviations ensure higher overlap of polishing trajectories, effectively preventing localized over-polishing or under-polishing.

- The repeatability of polishing robots should be ≤±0.05mm, a standard that meets basic polishing requirements for most general mechanical processing and hardware industries. Repeatability is also closely related to the robot's structural design, drive system, and control system precision. When selecting a robot, it is essential to comprehensively evaluate the core component configuration based on specific precision requirements.

2. Load Capacity

- Refers to the maximum weight a robot's end effector can support.

- When selecting a model, the total weight of the workpiece, end effector (e.g., fixture, polishing head), and polishing tools (e.g., grinding wheel, polishing wheel) must be accounted for, with a safety margin of 20%-30% to accommodate transient impacts and inertial forces during polishing. This prevents reduced motion accuracy and shortened lifespan due to insufficient load.

- Polishing robots are classified into three load capacity categories: light (≥5kg), medium (≥20kg), and heavy (≥50kg) based on operational requirements.

- The actual load is calculated using the formula: "Total load = Workpiece weight + End effector weight + Polishing tool weight," followed by applying a safety factor of 1.2-1.3 to determine the appropriate robot load category.

3. Working Range

- This refers to the spatial area accessible to the robot's end effector.

- The selection of the end effector must ensure that the robot's movement trajectory can fully cover all polishing areas of the workpiece without blind spots, while also matching the overall layout dimensions of the workstation.

- The working range is primarily determined by parameters such as the robot's arm length and joint range of motion, with different structural types of robots exhibiting distinct working range characteristics.

- For instance, six-axis robots, due to their high joint degrees of freedom, have a spherical working range, making them suitable for complex curved surfaces and multi-directional polishing operations.

4. Protection Rating

- A metric evaluating a robot's resistance to harsh environmental factors such as dust, water, and oil mist.

- Its selection must strictly match the operational site's environmental conditions. Protection ratings are typically expressed as IP grades, consisting of two digits: the first digit indicates dust resistance, and the second digit indicates water resistance.

- In polishing operations, environmental conditions vary significantly across different industries.

II. Industry-Specific Selection Strategies

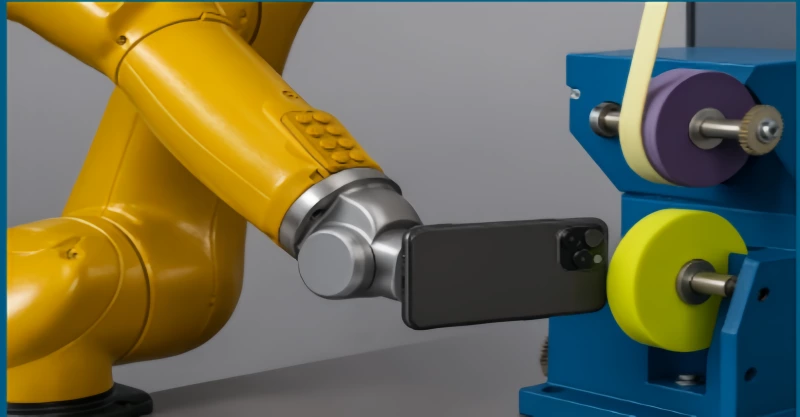

(1) 3C Electronics Industry: High Precision Matching of Precision Micro Parts

The 3C electronics industry is one of the most extensive applications for polishing robots, with its polishing workpieces primarily consisting of core components in products such as smartphones, computers, earphones, and smart wearables.

Typical workpieces include smartphone frames, back covers, camera rings, headphone housings, and laptop casings. These components exhibit distinct characteristics of "miniaturization, thinness, and high precision," typically made from materials like aluminum alloy, stainless steel, glass, ceramics, and composites.

In terms of polishing requirements, the 3C electronics industry demands extremely high precision, with most workpieces requiring surface roughness of Ra≤0.02μm. Some high-end products even demand Ra≤0.01μm to achieve a high-gloss, scratch-free appearance. Additionally, the industry's rapid product iteration and multi-variety, small-batch production modes necessitate polishing robots with rapid production changeover capabilities.

Furthermore, the working environment often involves cleanrooms with stringent requirements for dust control and environmental compliance. Given these characteristics, the selection of polishing robots for the 3C electronics industry must prioritize "high precision and low load."

Key Selection Points:

1. SCARA robots are the preferred choice, with a core focus on repeat positioning accuracy and motion stability.

- Given the minuscule dimensions of 3C components, polishing trajectory precision demands are exceptionally high, requiring repeat positioning accuracy strictly controlled at a ±0.02mm level.

- For ultra-high-precision applications, robots with ±0.01mm accuracy are required. Desktop robots offer advantages such as compact size, lightweight design, and minimal space occupation, making them ideal for cleanroom layouts.

- Collaborative robots, on the other hand, feature human-robot collaboration capabilities, enabling manual assistance in specific processes to enhance production flexibility.

2. To strictly comply with cleanroom environmental standards, high-protection-grade robots with high-efficiency dust recovery systems must be selected.

- In the 3C electronics industry, polishing operations are predominantly conducted in Class 1000-10000 cleanrooms, where dust concentration must be controlled to extremely low levels (typically ≤0.1mg/m³).

- Therefore, robots must have an IP54 or higher protection rating to prevent dust ingress that could compromise precision. Additionally, integrated dust recovery systems should be installed.

- These systems utilize negative pressure adsorption technology to capture micro-dust particles (e.g., aluminum alloy or glass particles) generated during polishing in real-time, achieving a recovery efficiency of over 99%.

Recommended Models and Applications:

- FANUC CRX-5iA Series Collaborative Robots. Capable of handling 5kg loads with 717mm arm length and ±0.01mm repeat positioning accuracy, ideal for precision polishing of micro components like smartphone midframes and camera rings. Supports human-robot collaboration and flexible production transitions.

- Elite CSF6 Collaborative Robot: Supports 6kg loads with 900mm arm length and ±0.02mm repeat positioning accuracy, equipped with a high-precision force control system for complex curved surfaces such as headphone casings and laptop shells.

- Yamaha YK-SP Series SCARA Robots: Handles 3-10kg loads with ±0.005mm repeat positioning accuracy and rapid movement speed, suitable for high-speed polishing of flat 3C components (e.g., smartphone back glass).

These models combine compact size, high precision, and robust protection to meet the core demands of the 3C electronics industry.

(2) Automobile Manufacturing Industry: Dual Adaptation of Heavy Load and Complex Surface

Polishing and grinding operations in the automotive manufacturing industry span multiple stages of vehicle production, involving diverse workpiece types that fall into three main categories:

1) Powertrain components, including engine blocks, cylinder heads, crankshafts, and camshafts;

2) Body and exterior parts such as doors, engine hoods, trunk lids, wheel hubs, bumpers, and rearview mirror housings;

3) Chassis system components like drive shafts, steering knuckles, and suspension arms.

Robot Grinding and Deburring Unit

Material variations significantly impact polishing requirements:

- Powertrain parts typically use wear-resistant materials like cast iron, aluminum alloys, and high-strength steel.

- Body parts predominantly employ aluminum alloys, steel plates, and composite materials (e.g., PP+GF).

- While chassis components mainly utilize high-strength steel and cast iron.

From the perspective of polishing requirements, the core goals of polishing in the automotive industry are to improve the surface quality and service life of components:

- For powertrain components, polishing is needed to reduce surface roughness, minimize friction and wear, and enhance engine efficiency.

- For body components, polishing aims to achieve a high-gloss, defect-free appearance and improve the overall vehicle aesthetics.

- For chassis components, polishing is used to remove machining burrs, avoid stress concentration, and increase structural strength.

At the same time, the automotive manufacturing industry follows a high-volume, assembly-line production model, which requires polishing robots to have high stability, high productivity, and the ability to operate continuously.

The working environment is usually an ordinary workshop with contaminants such as metal dust and machining oil mist, placing relatively high demands on the robot’s protection level.

Key selection points:

1. Based on the type of product you're going to polish

- For heavy-duty and large-scale components, six-axis industrial robots with high load capacity and extensive working range are recommended, complemented by positioners to enable multi-angle polishing.

- Workpieces such as engine blocks, vehicle frames, and large wheels typically weigh 30-100kg and feature large dimensions, requiring robots with sufficient load-bearing capability and operational range.

- When selecting models, prioritize six-axis industrial robots with a load capacity of ≥50kg and an arm length of ≥2000mm. These robots boast high structural rigidity, ensuring stable motion precision under heavy loads.

- Given the numerous polishing surfaces and complex angles of such workpieces, a single robot cannot achieve full coverage. Therefore, dual-axis or multi-axis positioners are essential to rotate and flip the workpiece, enabling the robot to polish from various angles.

2. Workshop environment conditions

- High protection ratings should be selected based on operational environments, with explosion-proof scenarios requiring compliance with dedicated standards.

- In automotive manufacturing, polishing operations often involve significant metal dust (e.g., cast iron, aluminum alloy) and machining oil mist. These contaminants can corrode robotic moving parts and electrical systems, necessitating protection ratings of IP67 or higher.

- Robots with IP67 certification are fully dustproof and can withstand 30 minutes of immersion in 1-meter-deep water without damage, effectively resisting oil mist and dust erosion.

Recommended Models and Applications:

1. ABB IRB 6700 Series: Load capacity 50-150kg, arm length 2.6-3.2m, positioning accuracy ±0.03mm, IP67 protection rating, suitable for polishing heavy-duty components like engine blocks and vehicle frames.

2. KUKA KR QUANTEC Series: Load capacity 90-300kg, arm length 2.5-3.9m, featuring high rigidity and rapid response, ideal for polishing large body panels and wheel hubs.

3. Yingle Technology YLR Series Flexible Grinding Robot: Load capacity 20-50kg, equipped with a high-precision main power control system (force control accuracy ±0.5N), suitable for polishing composite parts like automotive bumpers and rearview mirror housings.

4. Yaskawa MH24 Series: Load capacity 24kg, high-speed response, designed for high-speed polishing production lines of small-to-medium-sized body components.

(3) Hardware and Sanitary Ware Industry: Precise Control of Multi-materials and Surface Texture

The hardware and sanitary ware industry primarily produces polished grinding components for residential and commercial bathroom fixtures, including faucets, showerheads, bathtubs, sinks, door handles, locks, hinges, and rails.

These components are typically made of stainless steel, copper alloys, or aluminum alloys, with premium products utilizing titanium alloys or composite materials. As essential household items, hardware and sanitary ware products rely on their aesthetic appeal and durability as core competitive advantages.

Polishing and grinding of hardware tools

Their polishing requirements focus on three key aspects:

- First, enhancing surface gloss to achieve mirror-like finishes with high reflectivity and flawlessness.

- Second, improving corrosion resistance by removing surface oxidation layers to strengthen rust-proof capabilities, particularly crucial for bathroom products designed for humid and scale-prone environments.

- Third, adapting to irregular curved surfaces, as hardware components often feature complex geometries like faucet elbows and showerhead perforations, which pose significant polishing challenges.

- Additionally, the industry's production model typically involves multi-variety, medium-batch manufacturing, demanding high flexibility in robotic production line switching. The working environment is characterized by heavy metal dust and polishing agent residues, necessitating stringent environmental protection and safety standards.

Key selection points:

1. Select a medium-sized 6-axis industrial robot with a payload capacity of 10-20kg to enhance production flexibility and operational stability.

- Hardware and sanitary ware components typically weigh 2-10kg, while the total weight with polishing tools and fixtures ranges from 5-15kg. A 10-20kg-rated robot ensures a sufficient safety margin for stable operation.

- The high degrees of freedom (DOF) of 6-axis robots enable seamless processing of irregular curved surfaces, achieving comprehensive coverage without blind spots.

- To accommodate diverse production requirements, the robot must be equipped with rapid production changeover systems, including an Automatic Tool Changeover (ATC) system and a Quick Fixture Changeover system, with tool changeover time ≤30s and fixture changeover time ≤60s.

2. The system integrates enclosed work chambers with high-efficiency dust recovery systems to balance environmental protection and cost control.

- During metal polishing operations in hardware and sanitary ware manufacturing, significant amounts of metal dust (e.g., copper powder, stainless steel powder) are generated.

- These particles not only pollute the environment and endanger workers' health but also pose safety risks such as dust explosions.

- Therefore, enclosed work chambers are required to isolate the polishing area from the external environment, complemented by high-efficiency dust recovery systems.

- The recovery system employs pulse-jet bag filtration technology, achieving a dust removal efficiency of over 99.5%.

Recommended Models and Applications:

1. Elite CSH12 Collaborative Robot: Capable of handling 12kg loads with a 1400mm arm length and ±0.02mm repeat positioning accuracy. Equipped with a force-position hybrid control algorithm, it is ideal for polishing small to medium-sized hardware and bathroom fixtures, such as faucets and door handles.

2. Fanuc R-2000iC/165F: Supports 165kg loads with a 2655mm arm length, offering high rigidity and stability for polishing large-scale hardware and bathroom components such as bathtubs and sinks.

3. Estun ER16-1400 Series: Handles 16kg loads with a 1400mm arm length, supporting multi-parameter process storage for polishing various medium-batch hardware accessories.

4. KUKA KR C4 Compact Series: With an IP67 protection rating, it is suitable for polishing hardware and bathroom fixtures in dusty environments.

(4) Aerospace Industry: The Strict Precision Requirements of High-end Materials

In the aerospace industry, polishing operations primarily target core components of aircraft and spacecraft, including typical workpieces such as engine blades, impellers, nacelles, fuselage structural parts (e.g., wing beams, landing gear components), and aerospace engine nozzles.

These components operate in extremely harsh environments, enduring extreme conditions like high temperatures, high pressures, and high-speed airflow erosion, which demand polishing quality at the highest industrial standards.

- Material-wise, aerospace parts often use difficult-to-machine materials like titanium alloys, superalloys, and composite materials (carbon fiber-reinforced resin-based composites). These materials exhibit high hardness and toughness, making polishing extremely challenging.

- Precision-wise, surface roughness is typically required to be Ra≤0.005μm, with critical areas demanding Ra≤0.001μm. Surface integrity is also paramount, as any defects like scratches, sub-surface damage, or residual stress can severely impact the component's fatigue life and reliability.

Additionally, the aerospace industry imposes stringent requirements on production traceability, equipment stability, and safety. Operations are typically conducted in cleanrooms or specialized facilities, necessitating high precision retention and interference resistance from equipment.

Key selection points:

1. To achieve micron-level polishing control, ultra-high-precision industrial robots are selected, equipped with six-axis force sensors and laser measurement systems.

- Aerospace components require extremely high polishing accuracy, which conventional industrial robots cannot meet.

- Therefore, ultra-high-precision robots with positioning accuracy ≤±0.1mm and repeat positioning accuracy ≤±0.02mm are required.

- These robots typically employ core components such as high-precision ball screws, harmonic reducers, and optical grating scales to ensure motion accuracy and positional stability.

- Real-time detection of minute pressure variations during polishing enables micron-level force control adjustments.

- The laser measurement system continuously monitors surface roughness and contour accuracy of workpieces, feeding back to the control system for polishing parameter optimization.

2. Robots must maintain strict rigidity requirements to ensure precision stability under heavy loads.

- During aerospace component polishing operations, robots must operate continuously under heavy loads.

- Insufficient rigidity may cause minor deformations at the end effector, compromising polishing quality.

- The servo system must also provide high-precision torque control and vibration suppression to reduce vibrations during high-speed operations, ensuring smooth motion effectively.

- For example, in polishing aircraft landing gear components weighing approximately 30kg, the robot must operate continuously for over 4 hours under a 30kg load. Insufficient rigidity could lead to uneven polishing on the landing gear surface.

- However, using a high-rigidity robot ensures deformation remains ≤0.05mm during continuous operation, maintaining stable polishing precision.

Recommended Models and Applications:

1. ABB IRB 9100 Series Delta Robot: Features ±0.01mm repeat positioning accuracy and high-speed operation, ideal for polishing small precision aviation components (e.g., engine blades).

2. KUKA KR C5 Control System + High-Precision Six-Axis Robot: Supports 20-50kg load capacity with ±0.05mm positioning accuracy, integrates multi-axis coordination and digital twin technology, suitable for polishing medium-sized aviation parts like engine rotors and casings.

3. FANUC M-20iA/35M Series: Capable of 35kg load and 1831mm arm length, offers high rigidity and precision retention, ideal for polishing large aviation structural components.

4. Siemens System-Integrated Customized Robot: Enables high-precision trajectory planning and full-process data traceability, suitable for polishing ultra-precision aerospace components like engine nozzles.

III. Summary

In conclusion, the key to selecting polishing robots lies in "parameter alignment with requirements, function adaptation to scenarios, and quality assurance through standardized practices."

Companies must first identify core requirements based on their industry-specific characteristics, then match the robot's performance parameters and functional configurations accordingly.

By adhering to universal technical standards and implementation procedures, they can achieve efficient automation of polishing processes and maximize their value.